Almost all ‘super glue’ brands are an ethyl cyanoacrylate adhesive (ECA), with some form of gelling agent to make it easier to work with and occasionally some rubberizing agent to improve the shear strength. Such adhesives set by polymerizing. This means that a surface not ‘bonding well’ is dependent on two factors:

- Whether or not the adhesive actually polymerizes with the surface.

- Whether or not the adhesive can polymerize in such a way that it can ‘grip’ the surface.

As a general rule, ECA does not actually polymerize very well with most things. Baring other layers of cyanoacrylate adhesives and a handful of very specific types of organic molecule, it almost entirely relies on ‘grip’ strength instead of polymerizing with the material. This is why it’s so good at bonding to stuff like leather, fabric, wood, or coral (at a microscopic level, these all have very rough surfaces that the adhesive can work into and grip).

However, this has a notable side effect: ECA is not very good at bonding to very smooth surfaces.

Based on experience, smooth sheets of glass, high-density-polyethylene, PTFE (‘Teflon’), and even some forms of ABS work very well as work surfaces because of this.

That said, this same property, together with it’s relative flexibility and low shear-strength, means that ECA is not actually very good for fixing LEGO pieces. In particular:

- It does not really polymerize all that much with the particular blend of ABS that LEGO pieces are made of.

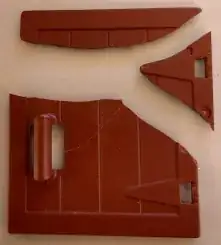

- Because of the specific blend of ABS involved, when a LEGO piece breaks it’s often smooth enough at a microscopic level that ECA will not grip it very well.

- Even if it grips well, the flexibility and low shear strength of polymerized ECA means that the piece will tend to flex more than it should, and will almost always eventually fall apart again on exactly the same break.

Additionally, some of the additives may damage or discolor the bricks.

Because of this, I strongly second the opinions of the various commenters on the question: You’re far better off using a solvent to ‘weld’ the pieces back together. Many ‘plastic cement‘ type things will work for this because of their typical composition, as will acetone. However, doing this ‘right’ takes a bit of practice, especially if the pieces do not fit together perfectly, and I encourage you to break a few other bricks to actually practice, as well as to test how well your chosen solution works.

I have personally had decent luck with pure acetone (you can usually get this from hardware stores or beauty-supply stores, the 70% stuff sold as nail-polish remover in many supermarkets does not work well), and better luck with methyl-ethyl-ketone (MEK) (which has actually been used by LEGO for making builds permanent), though MEK is harder to get legally in many places due to drug regulations (it’s on a number of drug-precursor chemical lists) and is a bit trickier to work with because it’s a much more effective solvent for ABS (IOW, you have to be quick and precise to get good results).

Regardless of what you eventually choose to use for this:

- Always do it in a properly ventilated area with appropriate protective gear (at minimum, disposable gloves made of something the solvent won’t dissolve). Many of the things you could use for this are nasty toxic.

- Always let it set for a while before testing the joint. The solvent has to pretty much completely evaporate for the joint to set properly. Testing it too soon will just break things again, and quite often in a way that’s more difficult to fix.

- Always let it sit for a few days after testing the joint before giving it to a child. You want to be absolutely certain that all of the solvent is gone before a kid puts it in their mouth.