I'm planning to float LVP (6.5mm) on 2nd store of our house (30+ years old). I'm currently working on a room that is 13' by 10'. I removed the carpet & padding, scraped and vacuumed. This is what it looks like... I can sand it down a little to smooth it up but it has seen better days.

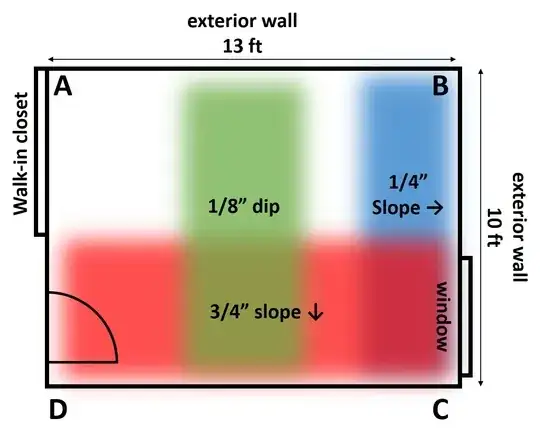

I then used a 6' long level to measure the flatness. Generally the floor is somewhat flat, with a 5ft wide trench that runs thru pretty much the entire width with a depth of 1/8" (roughly indicated by the green shading in the 2nd plot). The flatness tolerance of the LVP we're interested in is 1/8" in 6' or 3/16" in 10'. So perhaps our 5ft wide trench isn't too bad.

However, the floor does seem to have some sloping issue. One side has a gradual drop of 3/4" along the entire length (red shading in the plot). Along the other direction it also has a 1/4" drop over 5' on average (blue shading in the same plot). Both slopes are fairly flat (small dips no deeper than 1/8"). Forgive my very unprofessional plotting skills...

We recently had an engineer coming over for some other concerns. The engineer had this fancy laser thingy and found some ups and downs (no more than 1.5" over about 40') on the ground floor. But we were told it's not uncommon to see things like this over 30+ years and the engineer suspected that the house might have stabilized (house built on caissons). No cracks near window frames etc. So we were advised to monitor the situation. The engineer did not measure the 2nd floor (did examine the attic and whatnot).

Now back to LVP. I'm under the impression that generally sloping is not a major issue when it comes to LVP installation, but do correct me if I'm wrong. The 1/8" dip over ~5ft is close to the tolerance; the slopes shown in blue and red are pretty flat actually, i.e., the gap between the level and the floor is almost always 1/8" or less.

My questions are:

I'm gonna keep an eye on the sloping issue of the house in general, but would like to ignore it for the sake of LVP installation. Am I an idiot?

How should we further prep the floor? I have a palm sander but could rent a big one if needed. Could perhaps add another layer of plywood which would smooth things out I suppose.

I'd like to avoid self leveler. Not only the messiness but also the slopes - the thickest place would be like 3/4". Unless self leveler is the only choice?