I have a pressure gauge which threads onto a hose bib. I am trying to have the pressure gauge end up facing upwards in a readable position. Every time I try to start the thread at a different position such that the number of turns would have the readable face of the pressure gauge in the correct orientation it finishes at the exact same place.

Is the problem that the male thread will always start thread at the exact same spot on the female threaded piece?

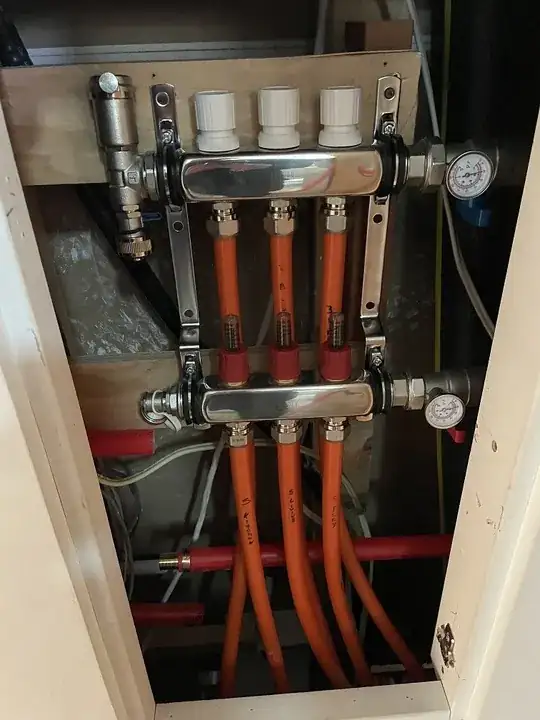

I've managed to spin the hose bib such that the pressure gauge is in the correct position but I have two manifold shutoffs that have temperature gauges which are in a similar state and since I didn't have much luck with the hose bib I worry I won't be able to adjust their orientation.

The only piece I am looking to change the orientation of is the temperature well. It does seem to have two nuts on the back so hopefully it does spin independently of the thread orientation.