I got some cheap aluminum windows for an outdoor room project, but I'm not sure what hardware to use to mount them. The windows have a nailing flange built in, but I don't want to use steel screws, or anything else thats going to cause corrosion super quickly. Can I just use aluminum screws to mount the windows to my wood framing? Is there a certain grades of stainless that will not cause corrosion with the aluminum?

Looking for suggestions.

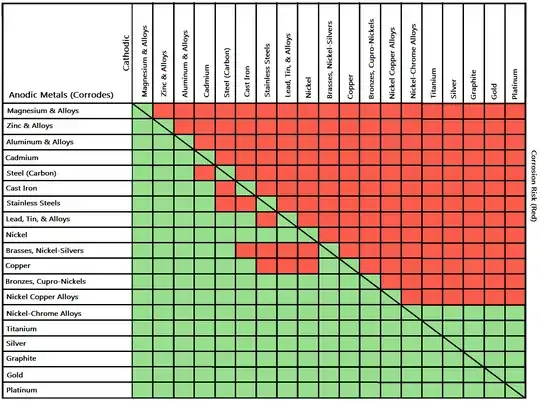

Edit: My main concern is the aluminum (anode) and stainless steel (cathode) effect which from what I understand could severely weaken the window frame since its aluminum.

Thank you!