CAUSES

I recognise those 1/4" shaft to drill to tap combos. They're very convenient for plastic or 3D prints, but in anything harder than brass or aluminium you'll do better to hand tap with a quality tap. Taps are absolutely somewhere that the cost and quality correlate, I've got one single M3 tap that cost as much as 20 of the combo bits.

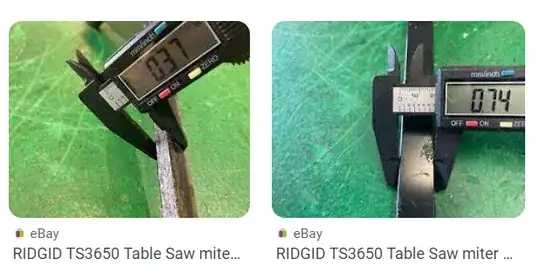

She's a bit thin in the middle, exactly where your's let-go.

Since tap wrenches don't take hex bits, you were probably power tapping this, and got ever-so-slightly off axis. If there was a warning, it went past too quick to notice.

There's also a chance the tap bottomed out in your hole, or it got hung up on swarf/chips.

In the future, hand tap difficult tasks and those where there is no spare. Use an alignment jig and plenty of appropriate cutting oil, and take your time.

EXTRACTION

Start by examining the part for wear and damage. Is it otherwise worth saving?

You can use the part after flattening off the tap stub, but to use the hole it needs to come out.

Start nice and gentle, with some warm air and penetrating oils. To get a grip on the tap, I'd use a couple of medium-heavy sewing needles pushed into the two visible gullets, and use an unscrewing motion. If there's movement, alternatively tighten and loosen edging it out. Keep the area wet with Kroil or CRC556 or almost any light oil. 3-in-1 or Singer oil would be better than nothing. If it comes out, the thread is probably okay.

If there's no motion after 10-15 minutes, try shock. Mount part in a vise (make sure its not squeezing on the stub) Use a center punch and a hammer, or an automatic center punch to rock the stub in the hole.

This will likely ruin any threads by making them a bit sloppy. Again, alternately tighten and loosen by tapping back and forth. Continue with hot air and oils, and even try remounting in vise so stub is horizontal.

Welding won't work - its too small. Give up on this idea straight off.

Drilling the stub won't work because its small and hard, and any drill will walk off into the surrounding metal. A carbide bit might work, but they're significant cost.

At this point, I'd accept the hole is dead and a thread insert is in your future. Drill one small hole into the part parallel to the stub, so it's just touching the stub. You're trying to make a relief beside the stub so it can be knocked sideways by the punch and then grabbed with needle nose pliers.

After extraction, you'll have a trench large enough to fly an X wing down.

- Fill it with weld, drill, and tap.

- Fill it with JB Weld (the metal one) and drill and tap. Potentially weak expecially for fine threads.

- Get a threaded insert like the 3D Printing people use and secure that in place with any good 2 part epoxy

- You might also choose to epoxy in a M3 nut, or perhaps something larger if a larger bolt is acceptable.

ALTERNATIVES

Start by pricing up a replacement fence

- What you had, and

- The expensive one you'd like to own someday.

If you break the part unrecoverably, then the first is your get-back-to-go cost. The difference between the two is your opportunity cost to upgrade now.

Good luck!