EDIT 2013-05-18:

Because it would be super easy, quick, cheap, and sound-deadening, I think the way to go is a cement door skinned in masonite/plywood with styrofoam pillows, built as I sketched out below. On one or both sides, Green Glue a second skin of 1/8" sheeting if desired.

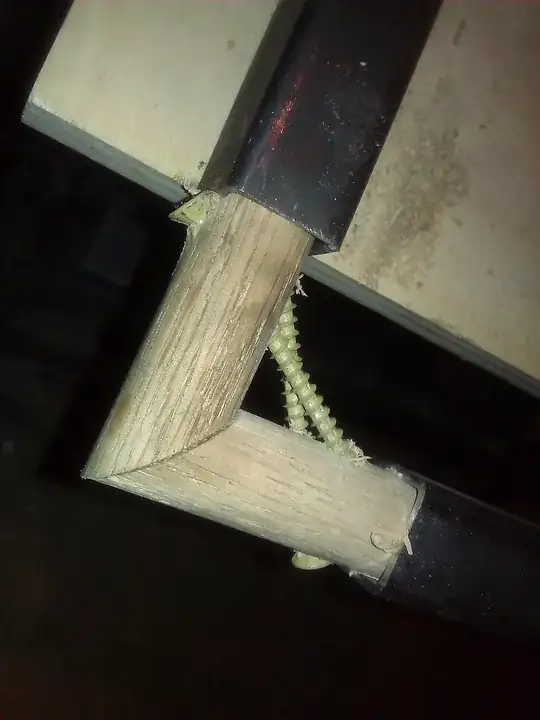

Still, if you are set on the steel tubing and MDF, another way join the four lengths that you already have is to find some corner braces that are about 7/8" wide. They would likely be about 4" long. Use a stack of them at each corner, embedding them in tubing with, say, an epoxy to take up any play.

EDIT 2013-05-17:

A) For a frame welded out of 1" square steel tubing, the ability to resist torsion boils down to the torsional rigidity of the square tubing over the frame's long dimension, about 6 feet in your case. Suppose the frame is 24" wide. A minor twist of 0.01 inches in a 6' length of the tubing would 'amplify' to 1/4" at the width of the frame.

B) Steel is strong, not particularly rigid. Your project needs rigidity much more than strength. So I suggest making a cement door ...

Cast the cement permanently inside a 'pan' made out of a sheet of 1/8" plywood/masonite framed with lengths of two-by glued down around the perimeter, and perhaps a 10" extra piece of two-by for the lockset.

When dry, cover the exposed side with a second piece of thin plywood/masonite.

Before casting the cement, line the 'pan' with plastic sheeting to keep the wood dry, or apply a generous amount of mold-release spray-on wax.

Embed whatever steel you desire into the cement, such as hardware cloth, or rebar.

If you calculate the weight ahead of time and consider it to be too heavy, embed squares of 1" styrofoam, or possibly shipping peanuts, though some types of the peanuts dissolve when in contact with water.

C) For the single-length method that I detailed below, the cuts can be made using a hacksaw or using a sawzall with a metal-cutting blade. The bends will not require much strength. As an alternative to kerfing+T-stock splines, you could avoid kerfing by using U-channel that fits snugly over the square tubing.

Make the frame out of a single length of tubing, cutting out four 90 degree wedges at the corners, a half-lap joint to joins the ends, and kerf the inside corners to receive T-stock as splines.

1) Start with 20' length of tubing.

2) Don't dado your door until after you have the frame built and tested.

3) Suppose the outer dimensions of the frame are to be X wide and Y high.

4) Cut the tubing to this length: X + X + Y + Y + 12".

5) Choose a side of the tubing that will be a side of the frame (as opposed to the outside or inside sides).

6) Apply masking tape to this side at four locations: A, B, C and D, where

- A = 6" + X/2

- B = A + Y

- C = B + X

- D = C + Y

7) With a pen, mark the tape at exactly A, B, C, D.

8) Cut out four 90 degree wedges centered a A, B, C, D from the inside side, leaving intact the wall of the tubing that will be the outside side. The wedges will need to be exactly 90 degrees, but 'fat' such that the cut-outs provide enough gap to bend the tubing to 90 degrees, but not so 'fat' that tubing bends past 90 degrees. Experiment with the scrap remaining from the 20' length.

9) Make a lap joint for the ends of the tubing by cutting off a 12" length of the inside half of the tubing on one end, and a 12" length of the outside half of the tubing on the other end.

10) Rip a 12" length of hardwood to square, such that it fits snugly inside the tubing (for safety, work with a longer piece, then cut 12" off).

11) Cut eight ~4" long kerfs on the inside of the tubing, a pair at each of the future corners.

12) Cut four 8" lengths of T-stock, say 1/2" x 1/2" x 1/16". The width of the eight kerfs needs to closely match the gauge of the T-stock.

13) At their mid points, cut the 'upright' all the way to the top. This will allow the lengths to be bent to 90 degrees with the uprights on the outside.

14) Bend the tubing into a frame shape.

15) Bolt the 12" lap joint together, inserting the 12" length of hardwood to to keep the joint aligned.

16) Slip the bent T-stock splines into the kerfs at the 4 corners.

17) Test the frame for its torsion. If satisfied, place the assembly on the MDF door blank to layout where the dados need to be routed.

My friend and I are wondering what nefarious acts you have planned for such a secure and sound proof room.

But I'm not convinced of the design - even if fully welded, the 1" steel tubing frame will still twist 1/4"+ out of plane with a small amount of force. So my answer is that the frame can't be made sturdy enough to counteract the forces the door will encounter due to the MDF warping due to your moisture differential.

I'd go with a sand floor covered by a free floating double layer of 1/2 plywood, and walls and ceiling lined with acoustic foam. The walls and door could be pocketed to hold sand inside of them as well. Sand is cheap, enviro friendly afaik, and dampens like nothing else.

But you seem set on MDF and metal tubing, so there must be good reasons. So I tried to answer your question as best I could within the limit of your previous statement of not wanting to weld ...