Nontrivial gaps are probably opening between the steel and the tabletop when you push horizontally. Insufficient stiffness of the steel ear plates is probably the root cause. The torsional stiffness of the horizontal steel tube flat to the table's underside could also be insufficient. A strategy to fix the problem without welding or adding braces is to use the tabletop's stiffness to harden things up.

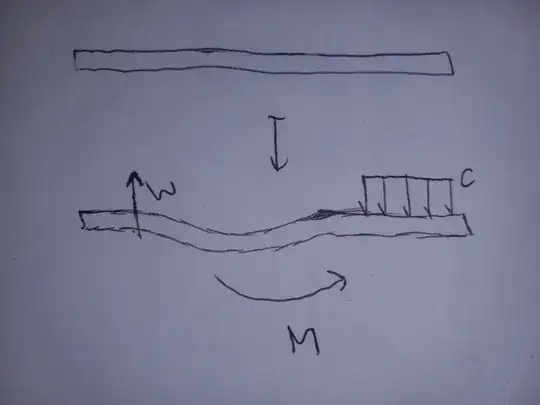

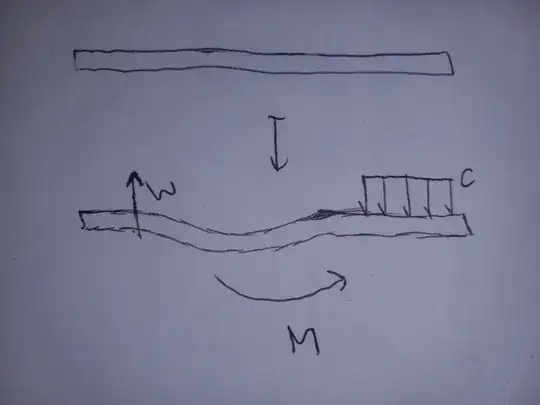

The ear plates are deforming when your horizontal load shows up as a moment acting at the ear plate connections. The deformed shape looks something like the following, where I've exaggerated the scale of vertical movements:

The moment, M, activates a withdrawal force, W, in the screw and activates bearing pressure, C, between the wood and the steel ear plate. My strategy for stiffening this up is to install additional fasteners on top of that lump to restrain it against opening. The designer probably put his single fastener at its current spacing because as the distance between W and C increases, the magnitude of the screw's withdrawal force decreases. Minimizing the withdrawal force minimizes the risk of the screw tearing out of the wood, so that was certainly what the designer had in mind. My narrower fastener spacing would increase that risk if I proposed a single screw, but by using two fasteners at my narrower spacing, the tear-out risk will actually go down.

I would locate 2 fasteners per ear at about 1/2" away from the face of the horizontal steel tube. If you're worried about over-tightening the screws out of fear of tearing the wood, don't be. You can abandon bad holes and drill additional holes (or install threaded inserts) as a work-around.

You may think that drilling holes in steel is outside your skillset, but it's not. Hardware store drill bits quite commonly are designed for drilling steel. Just look for "metal" on the packaging. Be sure to wear safety glasses to minimize the risk from metal chips.

If the table is still too flexible, then the horizontal tube is flexing between the steel ear plate connections and the vertical components. The space between the vertical components and the ear plates looks so short in your photo that I'm skeptical that this is contributing significantly to the table's stiffness problem. Again, tiny gaps may be opening, but this time they're between the ear plate location and the vertical component location. Same strategy, different position: Drill holes through the horizontal steel tube and then install additional fasteners to restrain these gaps against opening. I would install a total of 16 fasteners, installing four 2X2 grid patterns at 3/4" in from the outside faces of the horizontal steel tube and evenly spaced between the vertical components and the steel ear plates.