For several years I have lived with a wood fired bathtub. It works well enough except for scorching temps the bottom gets to. The work around is to sit on a board but when you have accidental contact it can be quite uncomfortable.

For several years I have lived with a wood fired bathtub. It works well enough except for scorching temps the bottom gets to. The work around is to sit on a board but when you have accidental contact it can be quite uncomfortable.

I would like to rebuild the system so that the drain pipe is a thermosiphon system. Given a decent pipe diameter would it flow if there were two Ts on a short vertical pipe the lower T beginning the cold end of the loop and the upper T the hot return.

Upon further thought and studying I've decided to add a second opening to the tub to avoid passing both cold and hot water through the drain. I will bore a second 1 1/2 inch hole through the tub wall in the ballpark of 4 inches from the bottom. This hole will act as the return for the thermosiphon loop.

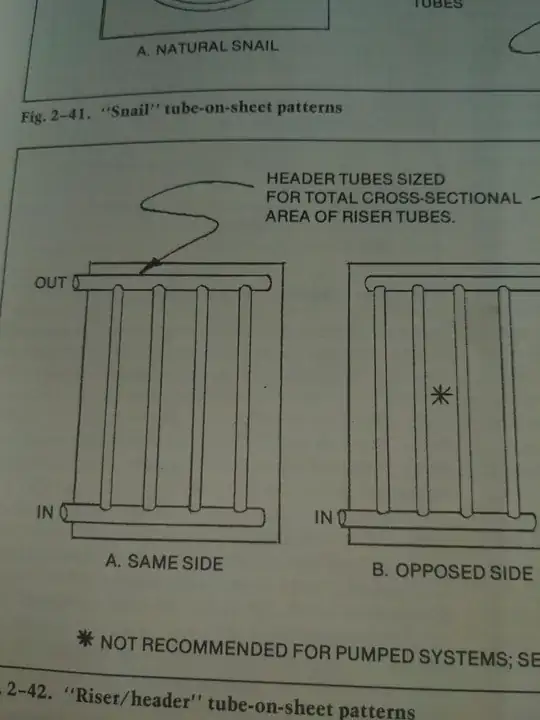

For my water coil I will be building a riser/header manifold. Using 1 1/2 inch steel pipe for the headers and 3/4 pipe for the risers. It will be pitched at a slight angle to avoid air entrapment.

I'm not sure if I should be using black iron or galvanized for the manifold. If it ever gets burned dry I would rather not release the zinc fumes but would like to avoid the rust of black iron. Hopefully someone has some insight on this. Also I'm unsure of what bulkhead fittings I could use for the drain/cold and return openings. Perhaps something NPT with ample gasket material to make it water tight.

I've added a picture of a riser header manifold to avoid confusion. It will be rather easy to have more surface area of manifold exposed to flame than the surface area of tub currently direct fired. Hopefully this will lead to decrease in the amount of heating time.