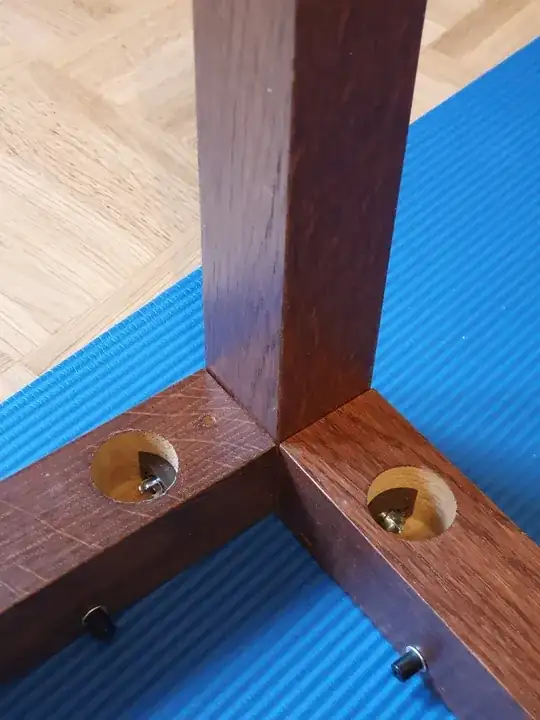

I bought a used table and the screws holding it together are of a kind that I've never seen before. Unfortunately, some of them are loose and I need to tighten them. They are impossible to turn with any of my tools. The problem is that when sticking something "horizontally" in the notch it can be turned only for a couple of degrees until one touches the wood, and then the screw has not yet turned enough such that the other notch (the other "half of the cross") would be accessible. Sticking any sensible screwdriver "vertically" in the screw is not possible either because there is very little room.

The holes around the screws are so small that a finger barely fits inside; they are way too small for turning the screws with a coin. Also an Allen wrench or a similar tool is no option because the ones that would be thick enough to turn the screws are too long (even on their short sides) to fit in the holes.

Here's a picture of the full table as requested, with a walnut for scale. It's just a small couch table. As observed in the comments, the table seems to be from IKEA's former Ekersby series.

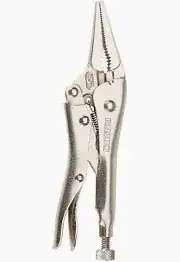

Is there a special kind of "bent screwdriver", "furniture tool", or any other tool that I could order online to tighten those screws?