I have a Whirlpool AKP200/WH (https://manuall.co.uk/whirlpool-akp-200wh-oven/) and the main element stopped working. The grill element still works, and the oven lamp, etc.

So I took the element out to have a look and found that one of its two male connectors was burnt up.

I then bought a replacement element hoping to fix, but as I explored further, I found that the wire had fallen through a hole in the insulation between the oven cavity and the back of the oven, and so I had to take the oven out to get it back.

I then noticed that the female connector on this wire had burnt up too (the one connecting to the burnt up element connector). So not a simple element replacement as I'd hoped.

I guess I need to fit a new female connector to the wire. The oven is old and a bit crap, but it did the job fine. So I'm wondering whether it's worth pursuing a repair, given I've already bought the new element.

How easy a job is it to fit a new connector? I assume it would have to be a high-temperature tolerant one? Would a repair shop do this sort of job?

Male connector burnt up (part of element)

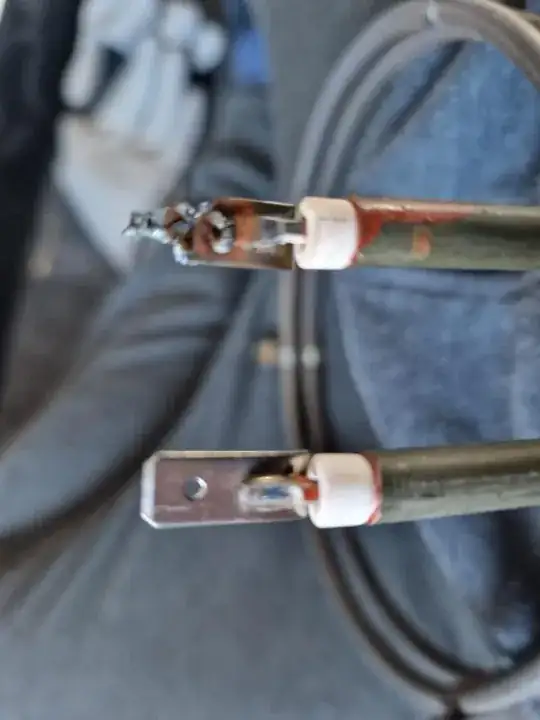

Good male connectors on new element

Female connector burnt up (part of wire)

Stripped some wire to see if it was damaged

Oven from the rear.

Oven from the rear. Lid off.

Update

So my friendly neighbourhood oven repair shop gave me a wire with the right connectors, but it was too short. So I cut that wire (i.e. removing the bad half with the burnt out connector) and crimped it together with the 'good half' of the wire I had using a butt connector, so I had enough wire to reach.

So far so good!