I have a Bosch handheld vacuum cleaner that works fabulously well. Today, however, a tiny plastic part that holds the dust container in place broke off during normal operation. The cleaner is two years old now, so I don't have warranty anymore; the only option would be to buy a replacement dust container, which costs quite a lot.

Therefore, I would like to fix the problem myself, if possible.

The locking mechanism works like shown below; basically, there's a button on the top of the dust container that is connected to an L-shaped piece of plastic, and hold into place by a small spring. If you press the button, the L-shaped part moves up, unlocking the dust container from the handset. I've employed my world-class illustration skills to bring you this sketch of the way it works:

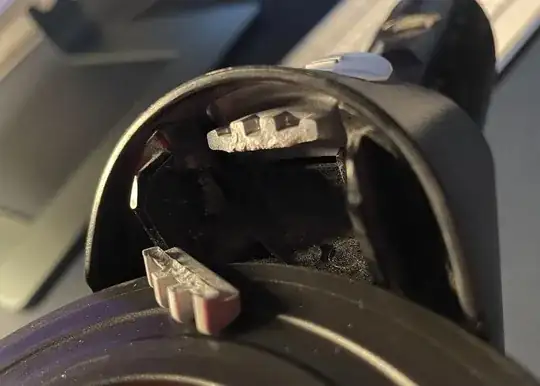

The L-shaped piece of plastic broke, and now looks like a sad lowercase "l":

I was wondering whether I could glue the pieces back together, and if so, what kind of glue I would need to use. I could imagine this part bearing quite a lot of force, given it transfers movement from the handle to the rest of the vacuum cleaner.

EDIT

On community request, I'm rephrasing the actual questions:

- Can a part like the one pictured here be glued, given the forces that apply on it during normal operation?

- Which glue would I need to use to do so?

- Is there a better way to fix the device?