Easy-to-buy standard screws

In the comments you write:

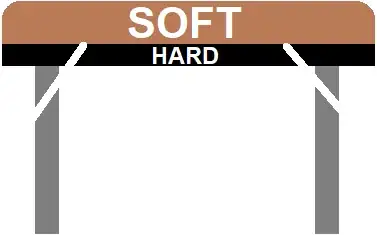

Get screws equal to the thickness of the wood/hard part

That's why I wrote relatively thin hard layer - for the thick part of the screw to get there, the whole point will be in the soft part. In short - not practical.*

But in the question you say "less than half an inch". Presumably it's not much less than half an inch as it has to take a person's weight, but you can buy 10mm (3/8") screws, or even 1/4".

You really could just use sharp screws that are shorter than the thickness of wood+bracket. Bought brackets would normally have 2 holes; use both.

Drill pilot holes, but slightly undersized so the screws are tight. Drilling very gently will allow you to find the thickness of the wood, especially using a wheel brace (hand drill, "egg-beater drill").

Blunt screws

You have other options though, which might be better than short sharp screws. A lot of flat-pack furniture uses short, fairly wide, un- or barely-tapered self-tapping screws. You can buy them down to about 12mm (1/2") long if you don't have a box of ikea spares, which is where I get mine. It is essential that you drill a suitable pilot hole with these, as close as you can get to the core diameter of the screw.

You can also take ordinary woodscrews and grind/file/hacksaw off the tips, getting the length right and removing the sharp point. Again, a pilot hole is needed, but if there's some residual taper you can use a tighter pilot hole. That gives you more choice, and is what I'd do if I just needed a few.

Using short screws is fine

Because it's only the length that's engages with the wood that does anything anyway. It does mean you need to be careful with the size of your pilot holes, and avoid too much taper.

A note on possible construction

Without photos, this is a bit of a guess, but upholstered chairs are often made by wrapping the fibre over a pad and chipboard/plywood, and stapling it to the bottom of the wood. Another layer of wood may be used outside that to hide the staples. That join may be held together just with the screws that join the whole seat assembly to the legs, or there may be additional glue or screws. Measuring the depth you have to work with is good, even if this means drilling a slightly larger extra hole and feeling down the side of it with wire or a fine drill bit. This doesn't have to be a precise measurement.