Rule #1: Manufacturers never include anything extra

The second set of hot and neutral screws is not for convenient daisy-chaining. Yes, they are commonly used that way, but that is not the reason they exist. The reason they exist is because some of the time a duplex receptacle will be split. This includes:

- Multi-Wire Branch Circuit (MWBC)

- One receptacle switched and the other not switched (commonly done in many places to avoid having to wire a ceiling fixture)

and probably some other situations. In any of these, a tab is removed so that the two receptacles are fed with separate hot wires. Depending on the situation, the neutral may be split as well.

But while there is a cost with each additional screw, there is also a cost (manufacturer for different production runs; distributors, retailers and electricians stocking their trucks for inventory) associated with having multiple devices. If you can take care of 95% or more of your non-GFCI, non-weather-resistant duplex receptacle needs with a single SKU, including:

- 15A regular circuit

- 20A regular circuit (a 15A duplex is legitimate on a 15A circuit, and in residential applications is commonly used)

- 15A and 20A MWBC

- 15A and 20A switched receptacle

etc., that makes things a lot easier to manage. You buy the basic 15A duplex by the case and the specialty items if/when you need them.

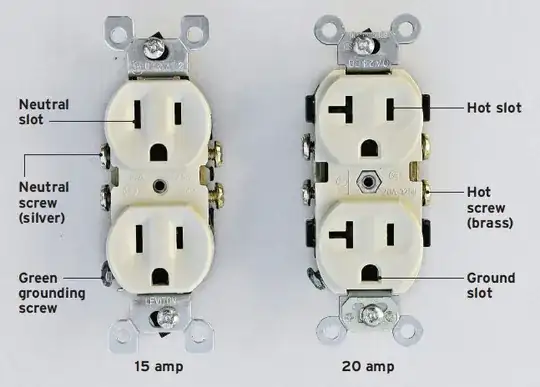

Rule #2: Ground is different

All grounds in the building are connected together. Because of that, there is no need for two separate ground screws on a duplex receptacle - even if the hot and neutral wires are separate the grounds are connected anyway.

It goes even further: With a good quality receptacle and a metal box, you don't even need the grounds screw at all! The yoke of the duplex receptacle grounds both receptacles to the metal box, which in turn is grounded to the rest of the electrical system.

Put these two rules together - one $ and one safety - and the result is that there is no reason to have more than one ground screw on a device.