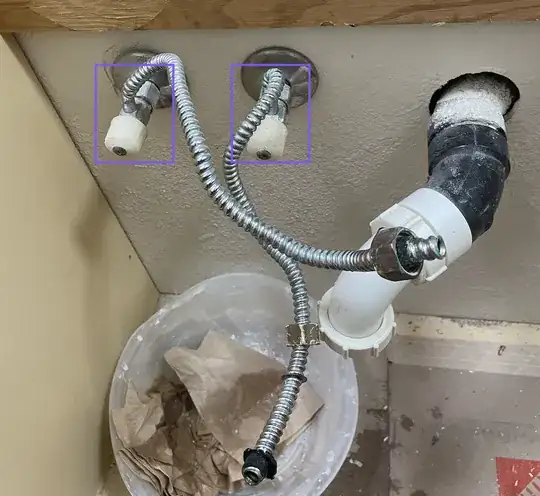

Typically removing/replacing the supply lines is done by simply loosening a bolt attached to the intakes as shown here:

However in my original seventies bathroom faucets they do not have a separable connection. It seems there are two choices:

- Remove the entire assembly at the wall

- Cut the braided cable at the spot that the nut would be in a newer arrangement.

I fear the second choice will end up with water all over the place. Actually I fear the first option will as well. Yes I could turn off the main water to the house, but I'm curious if there were a more surgical way to do this?

There will likely be a follow-on here: how to connect a new supply line, given there is no bolted connection location..