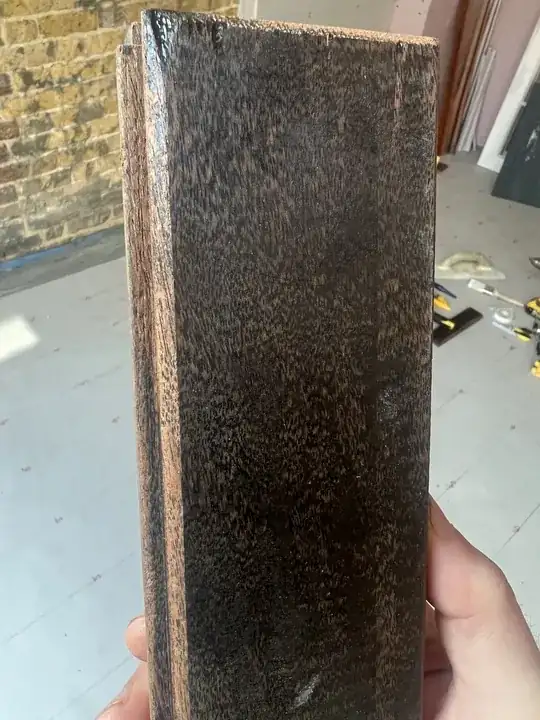

We have bought a large amount of reclaimed parquet floor (200 sq m) and whilst we’ve mechanically removed the majority of bitumen from the back (the solid clumps), there remains some bitumen residue: the whole rear side is black with slivers of wood colour just about visible.

We plan to lay it in herringbone style, blocks are approx 12x3 inches (actual size 305mm x 70mm).

Before we started the process we looked into adhesives that can be used and found Lecol 5500 which can apparently be used for this application. Whilst it doesn’t guarantee or mention in the data sheet, Lecol’s website states “Many contractors will simply take out the floor from the particular area, clean it as best as they can then re-install it using Lecol 5500 adhesive. This seems to work on most occasions but we do not guarantee anything and always advise care when dealing with old bitumen.” I called the technical departments of other companies like Bona who confirmed they do not have a similar product that works in this particular application.

The issue here is that Lecol also state their product should not be used to install parquet over a joisted subfloor: “if there is any movement (joisted sub floors), the bitumen residue seems to separate as the adhesive is a fixed product with very little tolerance to excessive movement.”

In our case we have applied self levelling on top of plywood (with suitable priming / gritted primer) and will then lay an additional layer of 18mm flooring grade ply on which to lay the parquet. However we will screw this down to the plywood under the self-levelling compound to sandwich the compound. So movement may be transferred.

I have done a small amount of laying parquet directly onto a very sturdy plywood subfloor on joists with this Lecol 5500 and I’m prepared to take the risk in this small area as joists are not long spans and are extremely well braced, sistered, etc.

But we are doing a larger floor in our living room which will be exposed to direct sunlight from large sections of structural glass above, and I’m not prepared to take the risk here.

Instead I’d rather use an adhesive that can tolerate some movement, which means the bitumen on the back needs to be completely removed.

We have experimented with putting the parquet blocks through a planer thicknesser. After manually removing the bulk of bitumen before this, we are left with only residue, and so the blades don’t get too gunked up and it seems to work well.

But each block of parquet has a different thickness (from 18-20mm) due to previous wear, and so when you set the planer to a given measurement it will remove different amounts of the underside. This means the tongues and grooves will no longer line up!

So we have first planed the top layer to get it to size, then when planing the bottom layer we know that it will remove the same amount of the underside.

This process is a lot of work. Benefit is that it will negate the need for a lot of sanding later I suppose…

We looked into chemical treatment of wood to remove bitumen but could find no viable option here.

The only other alternative I can think of is to plane ONLY the bottom sides, and cut the tongues off altogether which removes the need to first plane each block down to size from the top. Benefit is also that the planer always overcuts when the wood is fed in, if we only do it to the underside then that doesn’t matter but if we do it to the top side then it can affect the finish.

But it’s a shame as I do like the way tongues and grooves lock large sections of herringbone parquet together.

Onto my question. Is there a better way? Are the lengths I’m going to hear necessary, or am I overthinking? Would you sacrifice the tongue and groove for speed here?