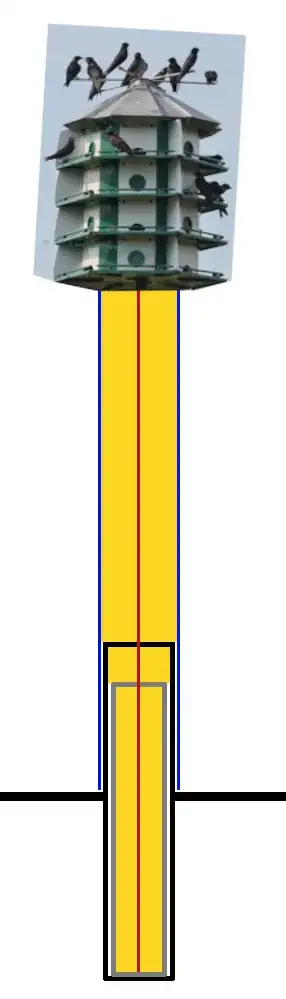

In Hurricane Beryl my Purple Martin birdhouse pole blew over when it broke off at the ground sleeve. In retrospect it was weakened by decades of metal fatigue and rust.

I would like to extract the remnant of the old pole from inside the ground sleeve so that I can re-use the sleeve for a replacement pole.

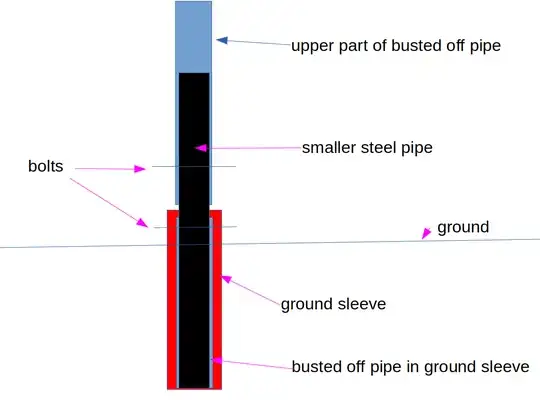

The pole is a 2 1/2 inch outside diameter galvanized steel pipe and the ground sleeve is a slightly larger diameter galvanized steel pipe anchored into the ground with concrete. The ground sleeve is three feet long and the inner pipe extends down to the end of it. The sleeve sticks out of the ground 8 inches or so. Referring to the picture, one can see that the inner pipe snapped off about an inch below the upper end of the ground sleeve pipe (unsurprisingly, it broke at the weak spot, where the retaining bolt holes were).

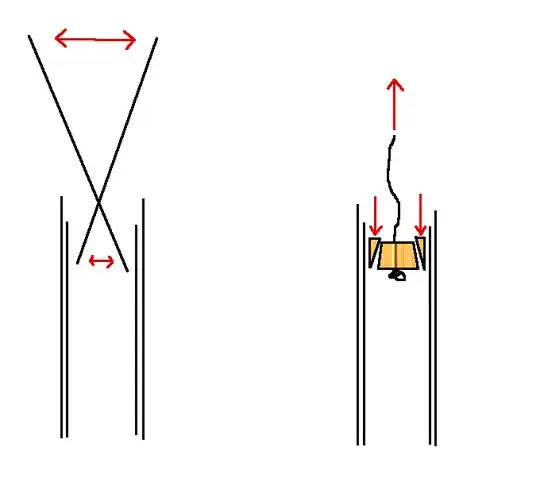

The inner pipe is not extremely tight against the outer pipe - I can stick the end of a large screwdriver between them and get some relative motion by prying. But the max displacement between the two pipes I can get is pretty small, maybe an eighth of an inch.

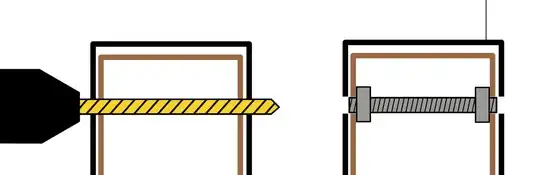

So my question boils down to, what tool or method can I use to "grab hold" of the inner pipe to pull it out? I expect it to take significant force, so it needs to be a pretty strong "grab". With the limited pipe-to-pipe gap and the amount the inner pipe is recessed, I can't get a pair of pliers on it, and I don't think the grip strength would be sufficient if I could.