When using a cordless drill to make 1/2" holes in 4x4 or 6x6 lumber:

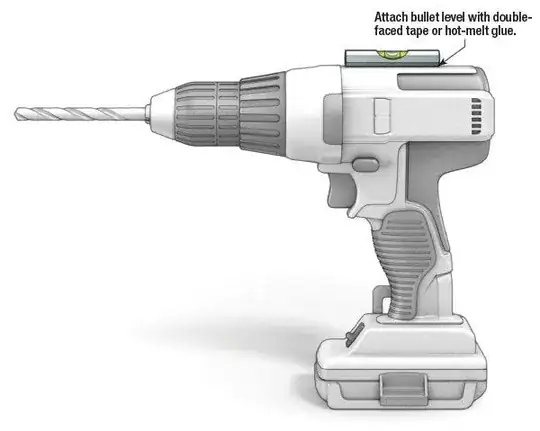

Despite taking my time, I find the holes I drill aren't perpendicular to the board. What can be done to drill better holes?

Off-grid location; no access to electricity or power tools like a drill press. Various applications.