Sorry to revisit an old thread, but having recently been pondering the same thing I have settled upon a solution that fits my setup.

I have an ikea mikael desk with glass top - it has full width wooden sides rather than legs and weighs a total of 30+ kg unladen (see https://farm3.staticflickr.com/2438/3857538226_ab3914ea19.jpg). With monitors etc on board it comes in at around 50kg.

I decided to use gas springs, the type you get on cars/campervans. I bought a pair or them for £23 (about $35) from fleabay which have 25kg lift and a stroke of 290mm.

These will be attached to the sides of the original desk and to a wooden bar which will sit on the floor, parallel to the sides. I also stumbled on an adjustable clothes rail (like http://www.amazon.co.uk/Premier-Housewares-Double-Hanging-Wheels/dp/B008VB2PPS) which has 4x adjustable length bars. I was given this and it has sat in the garage for a while. There are cheaper versions which should do just as good.

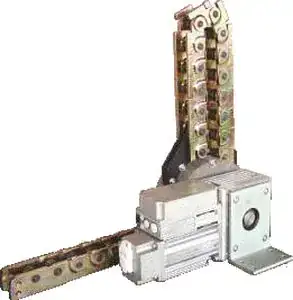

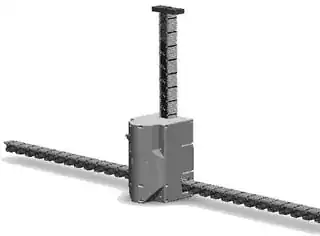

The 4 adjustable bars are made up of 2x poles which slide over each other, and a small locking mechanism which clips across. This mechanism won't hold much weight, maybe only 10kg max per lock, so wouldn't do to hold the whole desk up. The larger of the two poles attaches onto the original desk at the top and near the bottom and the locking mechanism sits underneath the join, with the smaller one attached to the new foot running parallel with the original side. One adjustable pole will be near each corner. The gas spring will run from the new foot to the original side and assist in lifting the desk - which should have an effective weight of only a few kgs now.

The extendable poles should keep everything running smooth and even, allowing the desk to lock at whatever height is required, and unless there is a lot of weight on the desk I should only need to lock the front, easily-accessible ones.

With a few bits of timber which I had lying around, the whole project should cost me in the region of £25 or so - if you were to buy everything new it may be £50. It's very much designed for my current setup so may not be suitable for all!

If wanted I can post a few photos on completion, maybe a video of it moving. I can imagine that most people have managed to solve their problems by now though!