This sort of intra-box tapping is considered OK when kept within reason

You are by far and wide not alone in the situation you run into, where a small control circuit conductor needs to be tapped off of a fat power conductor. In fact, this happens enough in industry that there are special tap conductor rules that apply to this situation, both within the NEC itself, and within NFPA 79 for industrial machinery. While the latter isn't directly applicable here, it's more relevant to an intra-box situation, and can be considered a subset of the NEC's "10-foot tap rule":

7.2.8 Location of Overcurrent Protective Devices. An overcurrent protective device shall be located at the point where the conductor to be protected is connected to the supply except as follows:

(1) Overcurrent protection at the supply shall not be required if all of the following conditions are met:

(a) The current-carrying capacity of each of the conductors is at least equal to that required for their respective load, in accordance with Section 12.5.

(b) Each connecting conductor to the overcurrent protective devices is no longer than 3 m (10 ft).

(c) The conductor is suitably protected from physical damage.

(d) The conductor does not extend beyond the control panel enclosure.

(e) The conductor terminates in a single branch circuit overcurrent protective device.

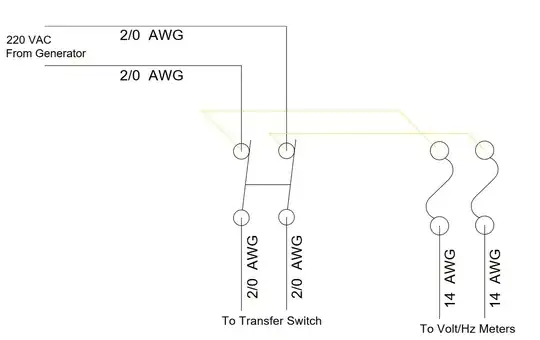

As a result, I'd consider a tap conductor situation acceptable. I'd use a set of 1/2" stud ring terminals atop the existing lugs (this sort of stacking of terminals is permitted at a base level by the UL White Book, provided the lug flats are making good contact) with 14AWG THHN, routed up and alongside the line conductors until it clears the inter-pole barriers, to make the tap. This rule also means you need to use branch-circuit rated overcurrent protection, which in your case means Class CC fuses in matching rejection fuse holders instead of "midget" or smaller electronic-style fuses, and mount the overcurrent protection inside the safety switch, which should be feasible given that you are running a 2-pole circuit through a 3-pole switch.