I've re-discovered my notes from the last time I made flow-fill. The full-size recipe I worked from is this:

2200 pounds sand/aggregate

1 bag type 1 Portland cement

200 pounds water

1 pound Fill-Flow (a Fritz-Pak product)

I mixed it in my little electric concrete/mortar mixer which comfortably holds a little less than two bags of concrete mix (80 pounds each), so I probably divided the recipe down to something like this:

120 pounds sand/aggregate

5 pounds Portland cement

11 pounds water - a little more than 5 quarts

120 grams Fill-Flow

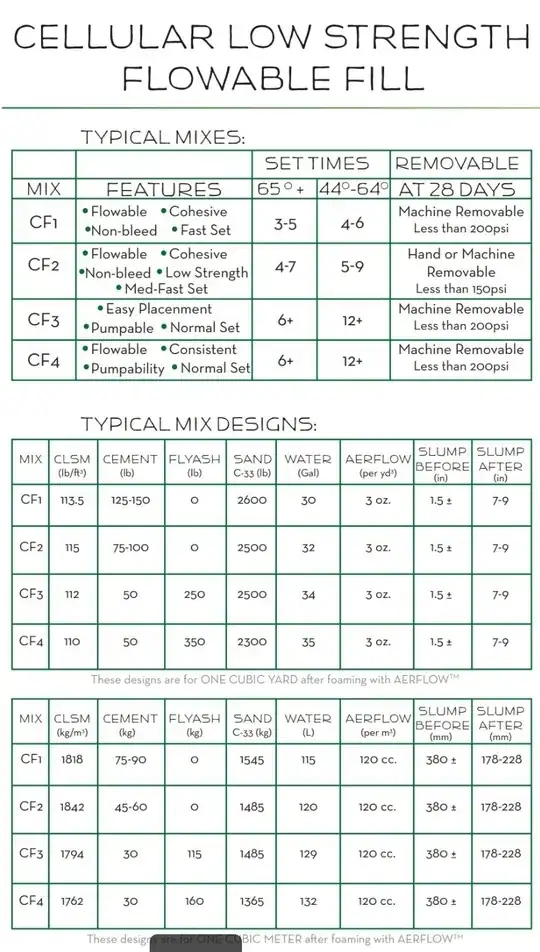

I wrote this without referring back to your recipe -- now that it's written I'm comparing, and though my batch is about 4x larger than yours, the ratio of sand, cement, and water seems about the same. The admixture quantity is dramatically different. But you're using a different product than I did. The Aerflow technical data sheet claims just 3 ounces of their liquid will treat a cubic yard of material, and indeed your batch is about 1/100th of a yard so 0.03 oz seems about right.

My use was to fill in a "pothole" - a vacuum-excavated pit dug in the roadway to verify the position and depth of a water main before directional boring crosswise to the utility. Through an 8" core drilled hole in the asphalt I had excavated a triangular slot five feet deep and widening to about 1 foot by 3 feet near the bottom of the hole. It had to be filled in a way that would prevent a sink hole forming later.

The foaming effect of the admix was stunning. I went from a mixer full of "not sure this is gonna work" to "holy cow this flows like cake batter!" The material poured/flowed out of the mixer very easily and there was very little bleed water that rose to the surface after it was placed.

Are you mixing this by hand? That could be the problem. The TDS suggests 5 minutes at "mixing speed" on a ready-mix truck. If I remember correctly that's about 11-20 rpm. Mixing too slow would probably not develop the foaming characteristic that makes the magic happen.

If a tumbling-type mixer isn't an option maybe a heavy-duty drill with a paddle as used for mixing thin set or drywall mud might work - but I haven't tried that.

Test run

Today I had an occasion to do a test run with the mix above. I excavated under a driveway to access and repair a conduit. We compacted what we could of the fill, but when it came within about 8 inches of the bottom of the pre-existing concrete, we couldn't compact any higher. Flowable fill to the rescue.

I estimated 120 pounds of sand and 5-ish quarts of water into the mixer. It turned into exactly what OP described: a lump of sticky, very damp sand with no flow characteristic whatsoever. I sprinkled the 120 g of Fill-flow into the drum and turned my back on it while weighing out a couple pounds of portland cement. When I looked again a minute or two later the mix was tumbling in the drum like a heavy batter. I shorted the cement a bit on this one -- only used 3-4 pounds -- and it did help the mix flow just a little better. Added water until the consistency looked nice and dumped it into the hole.

I had left myself a slot only about 4 inches high to introduce the flowable fill into the cavern under the concrete. It ran in somewhat well on its own, but a 2x4 jostled through that slot helped the fill liquify and run to the far reaches of the space. Four batches filled it up just right.