So, as it stands now I am hoping to build a hot tub from lumber. I've done ponds and makeshift pools and such, but this I want to be a lasting thing. It'll be framed and then lined with a thick rubber.

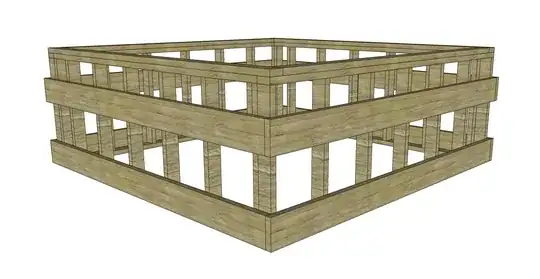

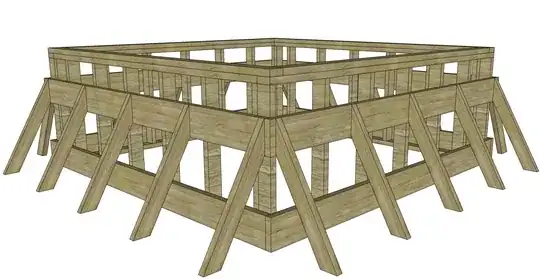

The hot tub will be rectangular or square, on a professionally poored concrete pad. I don't think I'm worried about weight of the tub pushing onto concrete, correct me if I'm wrong. I plan on using lumber in the 2x4 to 4x4 range. But could go bigger.

My concern is would the weight of the water put to much force pushing out? Thinking like either 6'x6'x3'. Or 8x8x3'. Maybe a 5'x10'x3'. I may increase depth to four foot.

Any of you guys see an issue with the weight of the water if I fully frame and support the outer structure? Or anything else?