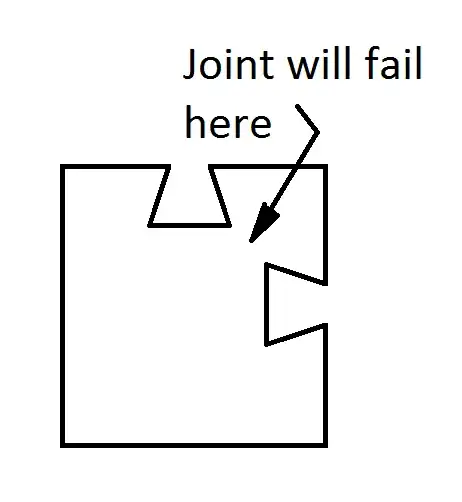

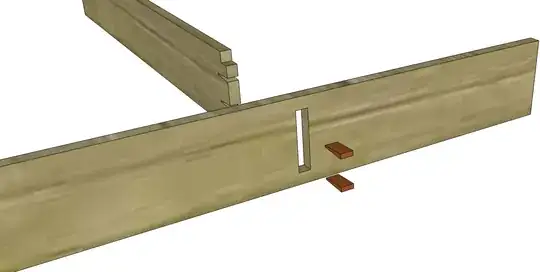

I'm designing a loft bed (here's a rough picture without the cross supports and other details). Right now, most joints will be mortise and tenon.

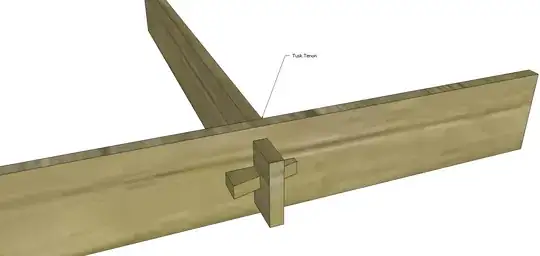

I'd like to be able to take the loft down to parts, and the simplest thing to do would be to disassemble it at the M&T joints. But that would mean they couldn't be glued, and my current understanding of M&T joints is that their strength comes in large part from the glue.

Am I missing something? Is there a way to build M&T joints that aren't glued but are still full strength?

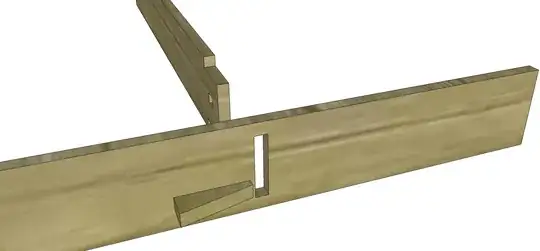

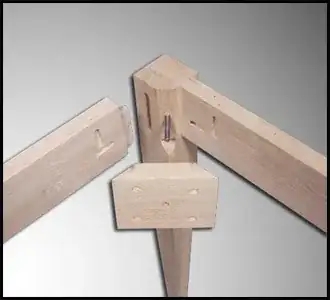

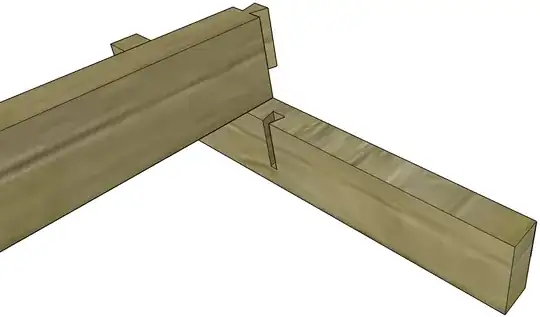

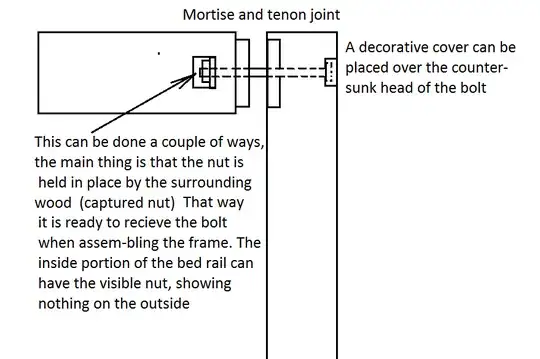

Edit 2013-11-16: I'd like to make these blind tenons. That makes @Jack's sliding dovetails really interesting. Since the joist structure will be visible from the underside, the aprons and hangar bolts for the corner are also interesting -- I wonder if there could be something like that to secure the non-corner joists...

Edit 2013-11-16: After watching a video about making dovetail joints, I'm going to go with @Jack's answer because they depict the answer to the problem. @HerrBag's comments (specifically stopping the dovetails) are, however, what make it a usable answer.

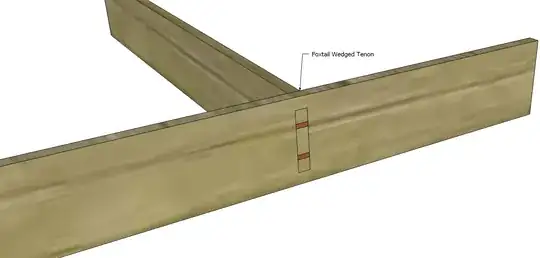

Just as a mention, a good hardwood needs to be used for the assembly. regular 2X4, 2X6s and other similar materials used in the construction of homes will be too soft, and when the joints are put under stress SPF, Hem fir, etc is going to compress and loosen the joints. To use this material you need glue and screws to hold all this together. That is not an option for you I think?

Just as a mention, a good hardwood needs to be used for the assembly. regular 2X4, 2X6s and other similar materials used in the construction of homes will be too soft, and when the joints are put under stress SPF, Hem fir, etc is going to compress and loosen the joints. To use this material you need glue and screws to hold all this together. That is not an option for you I think?