I would just drill pilot holes and screw it together, you don't need to do fancy cuts in the wood. If you need extra stability, put in a diagonal (diagonal cuts all the way across a board are much easier than notching). I would put in a small diagonal brace on each corner, although it would be easier to just use a large one across the whole frame.

I built a fairly nice CNC out of steel and aluminum and the framing members were butted togther and bolted to corner plates (which also added some diagonal support). The thing weights almost 200 pounds and I can lean it up on one corner of the X-axis frame and it doesn't budge at all. Butt joints don't look very nice, but they are easy and work just fine if you brace them properly.

While you could make your machine out of 1x4s and a dremel tool, I would at least use solid sheets of MDF and 2x4s or aluminum square tubes. Wood is cheap; most of your budget will be on your linear slides, screws/belts, motors, and controller(s) and it just isn't worth it to greatly limit the performance of your whole machine by skimping on what will end up being such a small part of your overall budget

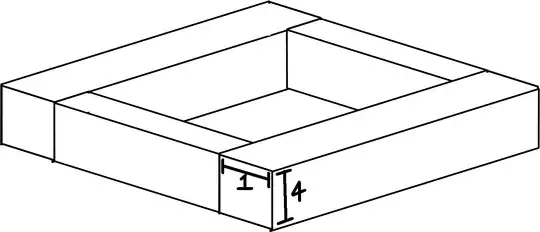

This is just the simplified view of the X-axis frame. It's just a normal rectangular frame..

This is just the simplified view of the X-axis frame. It's just a normal rectangular frame..