We have a pond with a fountain fed by a closed centrifugal pump. The fountain looks great... for 30 minutes. When its turned on, the pump sucks up sediment suspended in the water, and deposits it inside the hose. Over time this reduces the flow rate of the fountain to a trickle. If I use a water supply with higher pressure, such as that of the house, I can clean out the fountain hose (by simply forcing the sediment through the hose) and it runs perfectly - until it clogs up again.

The fountain is partly concrete, so a replacing the hose with a larger bore is not an option, therefore I need a new pump.

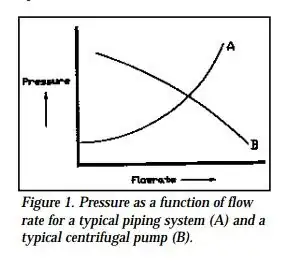

I am concerned though that buying a more powerful centrifugal pump will only result in the same problem. I am aware that you get either pressure or throughput with these, but don't know enough about fluid dynamics to be able to tell if, if I get a big enough one it stop it getting clogged up.

Ideally we would have a pump that maintained a constant flow rate, and increased the pressure as the line was constricted, until I presume some sort of equilibrium is reached where the pressure in the hose is large enough to displace the sediment on the walls.

Do I need something like a displacement pump, or will a correctly sized centrifugal pump do what I want?