Structural engineer here. This answer is late, but better late than never.

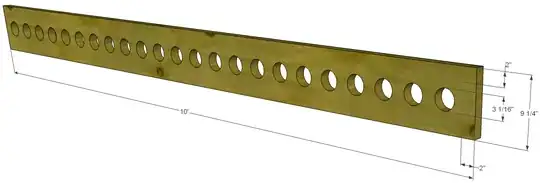

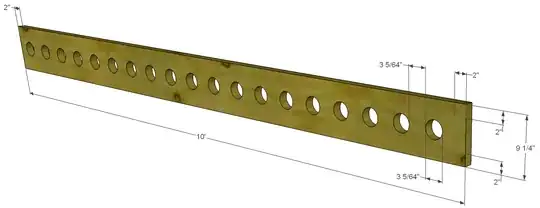

(EDIT: In general, avoid holes near the ends of beams, and notches near the middle of the beams. I would not recommend the detail shown in the image. You could swiss cheese it pretty well through the middle 1/2 or 1/3 of the beam span, but not near the ends. That level of hole drilling, in general, is not recommended in wood members. If that many holes are required, I would get a deeper member and stagger the holes.)

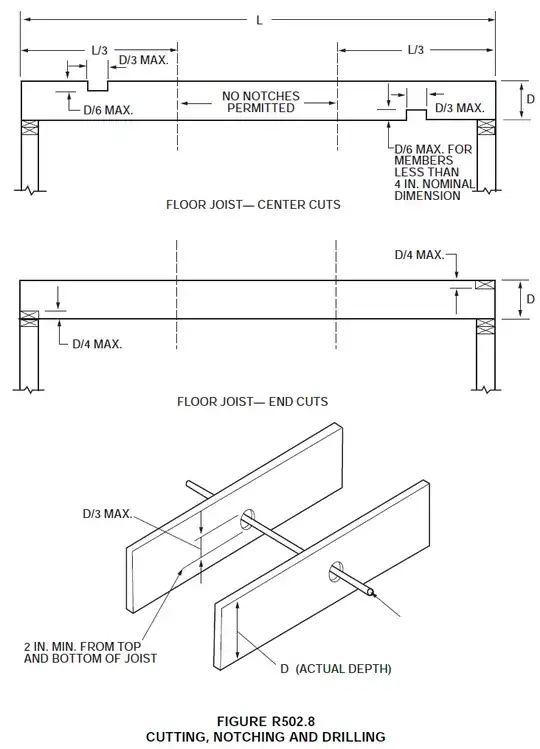

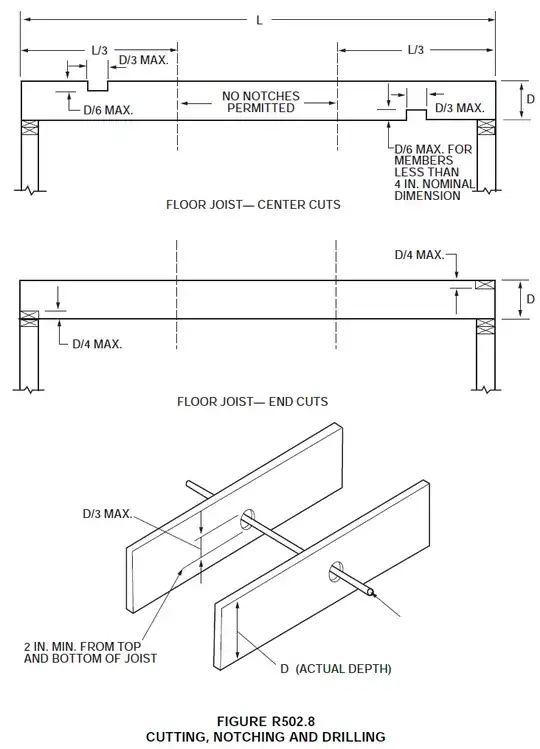

Notches (cut-aways from the edge) have more requirements due to the flexural (bending) nature of beams: the upper and lowest most fibers of the wood member take the most stress and control the design strength of a beam. See the figure linked below for specific requirements, taken from the IRC.

While the hole locations are less strictly controlled in the IRC, you want to avoid them in the outer ~1/4 of the joist span, as that is where the maximum shear occurs which is designed using the bulk of the wood material, not just the top and bottom fibers like in flexure. I don't think this is codified anywhere, but it's a good rule of thumb.

In summary: Holes should be limited to D/3 in the middle (1/2) of the span and I would limit holes to 1" or D/8, whichever is smaller (this is not codified, but is reasonable), for the outer (1/4) of the span, staggered. Holes should never be outside the middle (1/3) of a member. Weyerhaeuser recommends 2x[Hole Diameter] minimum clear distance between holes for their TJI products, which would be a conservative rule of thumb to apply moving forward. I also wouldn't drill holes above each another.