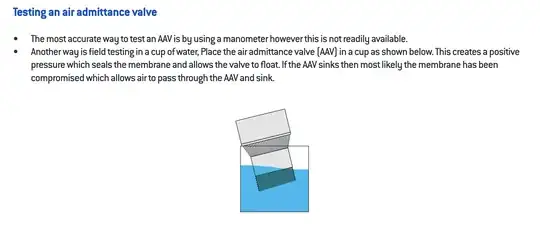

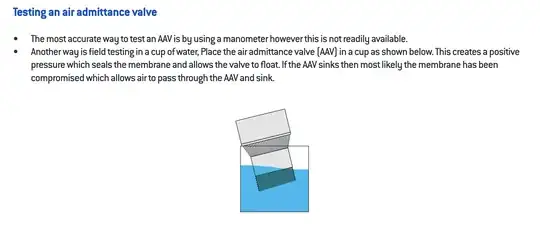

In my limited research I was also not able to find much about testing AAVs but I did find this document by IPS. At the end of this document it has a section on testing AAVs and I'll just share a screenshot since it includes a diagram.

As you can see in this image, if you put the AAV into water, it will put pressure on the valve. The valve should not allow any air to escape, similar to how sewer gases should not escape during regular use. I believe if you put it in 1 inch of water and no air escapes, that is basically testing the pressure to 1" of water column (WC) which is what Wisconsin requires (although their form also requires a master plumber signature for some reason, even though homeowners in my area can DIY, so that doesn't really make sense as a requirement).

To ensure there is 1" of water column pressure, I believe you could get a tall cylinder with water in it, put a manometer (small hose with water in it) into the AAV, put the AAV in the water, and watch as the water in the hose moves up 1/2" and down 1/2" on the other side. This, I believe, is 1" of water column. In reality this seems annoying and is probably easier to just use a real manometer but theoretically I think this would work.

If you're a plumber, please provide a better answer because this is crazy.

Note: 1" WC equates to 0.03609067 PSI

Another idea that is maybe a little more expensive but more permanent and better is to get a lower pressure gauge (1/4" in size) and thread it into some PVC that you can couple with an AAV. Here is a good demonstration of how you would do that: https://www.youtube.com/watch?v=Zy7LTWniPuQ. Then you would put in a bicycle pump valve and put a small amount of pressure into the sealed pipe. Alternatively you could just put in the bicycle pump valve (shrader valve) and use a low pressure gauge that fits the shrader valve.