I'm planning on building a home climbing wall, made from a mild steel subframe. It will probably be around 10 feet tall approx.

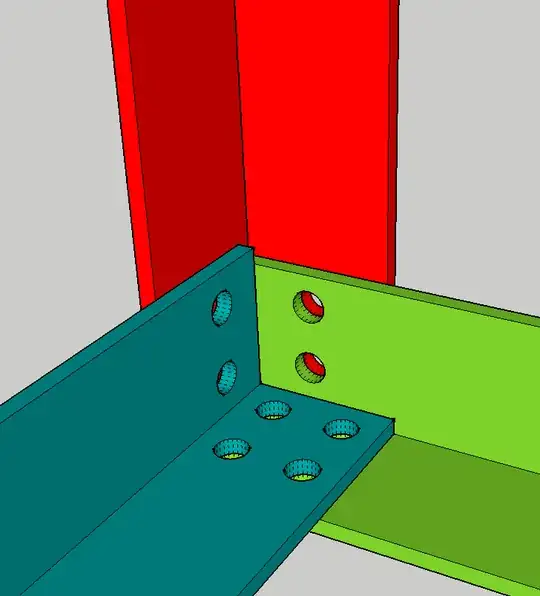

I was thinking along the lines of using mild steel angle, cutting to size, drilling bolt holes then joining the peices together.

Like this:

Does anyone have any idea as to the strength of such joints compared to welding?

Also, the wall will be freestanding, not attached to an existing wall so I'll need to lay some foundations, for this I was hoping to get away with a concrete base with bolt holes alligned to accept the sub frame being bolted straight to it. This would allow me to remove the wall and not leave a big RSJ poking out of my garden or some other such thing.

So my other question is, would such a foundation be acceptable? Is their other longer fixings availiable that could take the place of using bolts?