I want to buy an inverter-generator to run my Trane heating system in case of a power outage. The Trane is on a 20 amp circuit. The sticker says it needs a minimum of a 15.2 amp circuit.

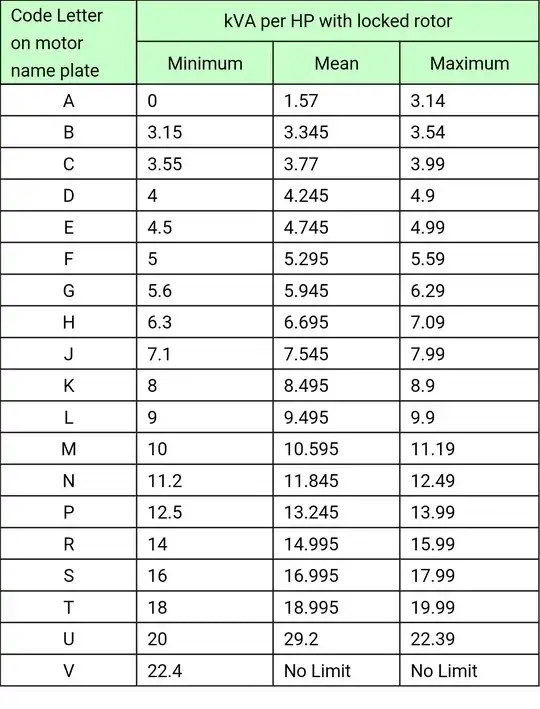

My question is, how do I determine (not estimate) the surge amperage of the 1 hp blower motor in my Trane heating system?

The inverter generators I have seen have max outputs of 2,000, 3,000, or 4,000 watts. I am trying to figure out if any of these will run my heating system. It seems the critical issue is the starting current of the 1 hp motor.

How might I go about measuring the starting current of my heating system?

Update: My HVAC 1 hp fan motor is constantly running- on low if not providing heat and on high if it is providing heat. Based on that, it seems to me that I need to use the in-rush amperage, since the theoretical calculations are all not relevant to my situation. Thanks.