I recently bought a used aluminum boat that has 12v wiring for lights.

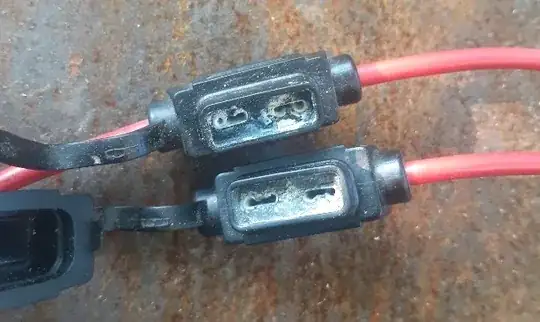

The wiring has inline "waterproof" fuses similar to this: https://www.princessauto.com/en/in-line-fuse-holder-with-led-indicator/product/PA0008684805

When I looked inside the fuse compartments (which were full of water), the fuses weren't blown, but they were heavily corroded, so they didn't conduct electricity.

I've replaced the fuses and cleaned the sockets/enclosures with a wire brush. Now, electricity is being conducted, as expected.

Question:

Is there anything I can do to prevent the new fuses from corroding in the future?