EDIT: Two things I didn't (but wanted to) point out in this answer -

- The gauge sweep at key on should be normal. I believe GM does this so the gauge will re-calibrate every time the vehicle is started. It basically shows you the gauge (the dash portion) is working as intended.

- If you at ALL think this is a mechanical issue with the oil system, don't operate the vehicle again until you can put a separate, most likely mechanical, gauge on your engine to ensure you ARE actually getting oil pressure. You could probably verify oil is getting up to the rockers as well to assume the pump is performing. You do need to verify, though, or engine damage may be occurring even before you start hearing noise.

Most likely this is an electrical issue, but who knows at this point where the problem lies.

The pressure sensor used on the LS engines (most if not all) have three pins which equates to three wires going into them. I don't know exactly what each does, but I assume they are: power (most likely 5vdc); ground; signal to the ECU. It will read 0-5v depending on the amount of pressure put against the sensor from the oil.

First thing to check is to pull the electrical connector at the sensor, then check to see if there is any difference in the gauge reading or if the code goes away or changes. What you are trying to see here is if something does change, it is most likely a problem with the sender. If the electrical circuit within the sender is shorted, it could be causing the issue that you're seeing. If you see any change in behavior when you pull the connector, my suggestion is to go ahead and change out the sensor with a new one, because this is most likely the culprit.

NOTE: The sender is most likely the culprit anyways, because it is the "thing" which will most likely go bad. It doesn't mean wiring can't go bad, it just means wiring is less likely the culprit.

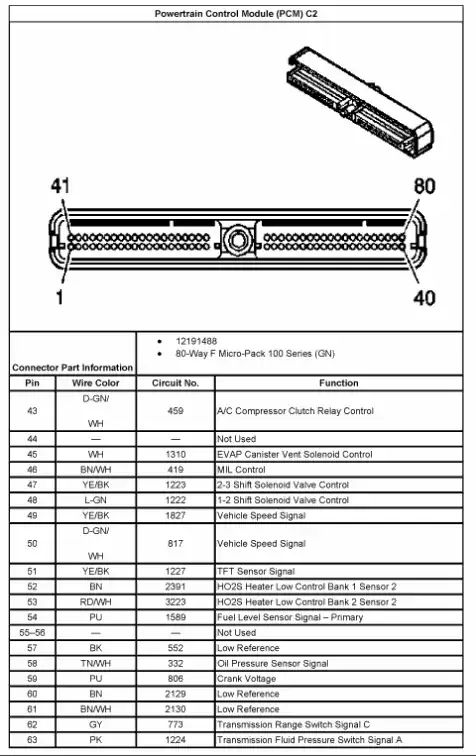

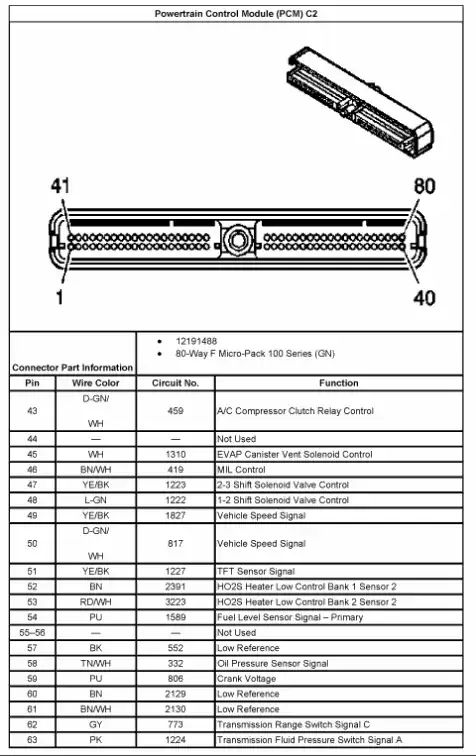

If you don't see any change in behavior when you pull the sender's connector, you'll need to trace the wiring. According to this chart, the sender signal should be a tan/white (assume a tan wire with white stripe) which goes from the sender back to the ECU and ties in on ECU connector 2, pin 58. Your Yukon should be a drive by wire (DBW) throttle body, with ECU connectors being Blue/Green. The connector you're checking should be the green one. I don't know which pin on the sender's connector it is, but it will probably be obvious as there should only be three there.

With the three wires, you'll check the tan/white wire for continuity between the ECU and the sender connector. If no continuity, there's a break in the wire somewhere which will need to be mended. One of the other two should provide +5vdc with the key on (power from the ECU) while the final would provide a ground. I don't know if this is a ground to the ECU, but it most likely is rather than going directly to the body. Because of this, the key may need to be on to test this as well. Obviously, the PCU connector will need to be in place to test the power/ground. It will need to be disconnected to test the signal wire.

If you still haven't found a smoking gun, with both the ECU connector disconnected and sender connector disconnected, check for continuity between the pins of the sender connector. If there's a problem here, you are going to see a short between the power and the tan/white signal wire, but check between all three (two at a time, of course).

If you find continuity between any pair of pins, you need to trace this back and find the short. This is an arduous task, but if there is a short, you'll usually see a "rub" spot in the wiring harness where wiring has made contact with the body in some way, bringing the wires together to create the issue. Fix any wiring as needed to solve the issue.