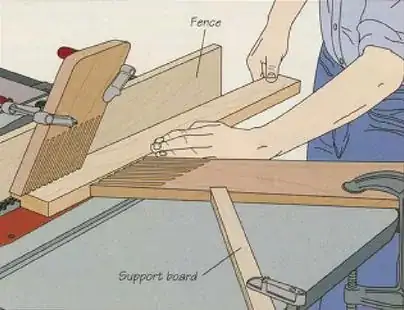

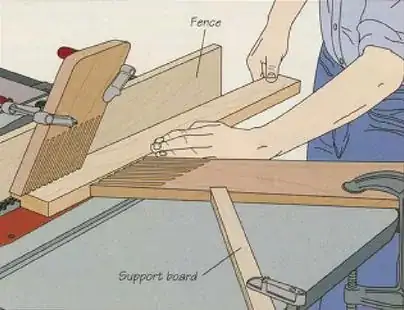

While a push stick is a great first step, one or more featherboards with a push stick really is the best solution here. When they are well secured, they will prevent nearly all kickback, either on a router table or table saw. When kickback occurs with just a push stick you are still relying on your body to resist the kickback, with featherboards kickback is resisted mechanically.

As an added benefit, featherboards apply constant pressure at the bit and will give you more accurate cuts.

They are basically free to make yourself with scraps, or you can buy ones that clamp to your miter gauge slots.

Also, pay very close attention to which direction you are feeding the wood, or moving the router. If the wood is being fed in the direction shown below it is called climb cutting and can be very dangerous. In a climb cut, the bit is cutting on entry and has the effect of pushing the router away from the workpiece. If not resisted by the operator, the bit can exit fully from the cut and "climb" its way along the workpiece. For a router running at 10,000 rpm, this can mean a sudden loss of control and high risk of injury.