I am renovating my fireplace that was original to the home built in 2007. It was not to our liking, so I am doing a resizing to make it fit better in the room. In doing this I needed to change the length of LP gas line going to the firebox. It is set up for gas, perhaps a log lighter or gas log, but I am using it as a woodburning unit as the prior owners have in years past.

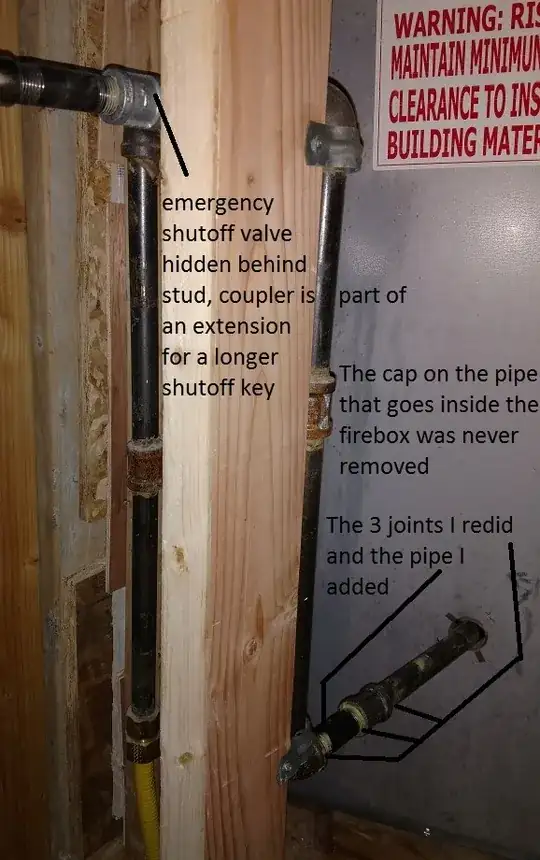

I have already changed the length of the pipe so what extends into the firebox is the same as original. I have tested it for leaks, there are none. To test it, I turned the emergency valve on to pressurize the new length of pipe, and sprayed a soapy water solution on the 3 joints that are new. I did this 3 times over a 3 hour period and will do it again before I put the last sheet of drywall in place to cover it. I will close the valve after I find everything satisfactory.

The question is, since this was done years ago and the firebox did not blow up, will my charging the line the way I have trap gas between the valve and the cap that is in the firebox? I presume that some possibly may have entered the pipe beyond the valve since it had to pressurize the little that it did.

Not knowing the procedure the original installer did, makes me wonder if they did the same as I, but knew that it would do nothing as proved over time, that the amount of expansion from the pipe getting hot would not allow the pipe to bust (blow up). If there are any plumbers or fireplace installers out there that have done the same set up as I have here, and the firebox lived to tell about it, please chime in.