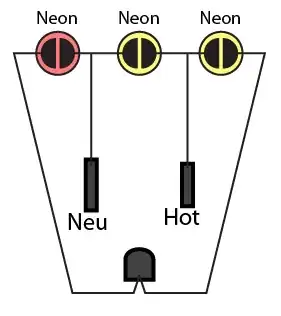

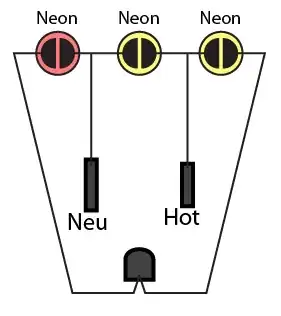

On those hokey outlet testers, the legends are about as useful as a "magic 8-ball". They are wild guesses as to the problem. That said, the simple ones are just this, which give you 3 neon lamp tests at once. On my simple one, I wrote NG, HN and GH under the lights, peeled off the legend, and suddenly it's a Really Useful Tool.

Yours, unfortunately, appears to have some added digital logic to wreck that simple functionality.

Here's your problem:

The new panel has a grounding wire that runs from the panel grounding

bar to outside and is connected to a copper rod sunk 6 ft into the

ground.

and fullstop. Let's review. Current travels in loops. Current doesn't want to get to ground, it wants to get to source. For hot, source is neutral. The grounding shield is still designed to return wayward hot to source, and it does that via the one neutral-ground bond in your main panel.

Of course for natural electricity, lightning and ESD, source really is ground.

The problem is, in your case, you've correctly separated neutral and ground in the subpanel, but your only connection between shed and house is a bunch of dirt. So I see four ways to fix this, worst to best:

Unhook the grounds

Currently your GFCIs are your only line of protection. The grounding system actually works against you, because if a machine has a ground fault, it's going to "light up" the entire grounding system and make it dangerous. Of course, the the GFCI's should prevent this.

Use the grandfathered method (if allowed)

Normally you separate neutral and ground in the subpanel. Under the method now illegal, which you may be grandfathered into, outbuildings could ignore this, bring over a combo neutral-ground, and tie neutral to ground in the subpanel. In this scenario, you would do exactly that.

Convert to 120V; re-task a Hot to be Ground

If you don't really, really need 240V out at the shed, you have the option to switch the service to 120V. You abandon a hot to free up the extra wire.

If one of your conductors is bare wire, or smaller than the others, it's probably now the neutral, and must become the ground. If one is green, it must be ground. Otherwise, pick any. It's important not to mix up neutral and ground, so I would make one change at a time in the main panel and measure how it affects the subpanel.

You will end with a subpanel where half the breaker positions don't work, typically every other row of spaces. Move your breakers to the live spaces, and you're done. If you need empty fillers, I just use $4 plain breakers. They're not much more than the hard-to-find blank covers, better built, and hey - you have spare breakers. Piece of red tape with N/C and you're all done.

Run a ground wire

The nuclear option here is to run a separate, physical ground wire. This does not need to use the same route as the conductors - for instance if it's possible to circumnavigate your driveway, you can do that. Your required size is smaller than #2 but must be copper unless you install it using a proper wiring method.

You do not need to tear out the existing 3-wire cable and replace it with 4-wire cable. That would be a silly waste of money.