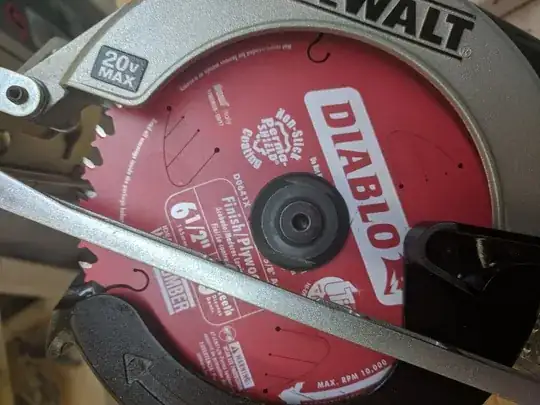

I need to change the blade on my Dewalt DCS391 circular saw for the first time. The blade clamping screw is for an hex key left-hand threads, but I can't unfreeze it no matter how much lever of pressure I put on it, I'm starting to eat the screw head.

I'm following instructions from the manual with no luck.

Suggestions?