My toilet tank is held in place by two screws, which have rusted so much that the shape in their head is almost completely disappeared. On the opposite side, they are held in place by two wingnuts made from plastic. I tried to losen one of them with pliers, but that only ended up in one wing breaking off.

Main question is: what is the best way to get it off, given the wingnuts?

I'm aware of this other question, and this is the answer I like most, which suggest using a mechnaic's nut cracker, but I have a few follow-up questions to that:

Is there a way to remove the bolts without cutting/drilling/breaking them? (Not that I need them, I'm just afraid of damaging the tank or the bowl in the process.) E.g., I read somewhere else that WD-40 might be enough, but did anyone actually try this with success? Also, where would I put it: between the wingnuts and the toilet bowl? Or below the head of the bolt? (It would be quite difficult to get into both places...) Or maybe with some rust-solvent?

Can the wingnuts also be broken by the mechanic's nut cracker? (Obviously, plastic would be easier to break than metal, but the shape might not make it easy to access.)

Also, as far as I see, this is a tool mostly for car shops (as the name suggests), so I guess a plumber would use some other tool. Which one would it be?

The two rusty bolts inside the tank:

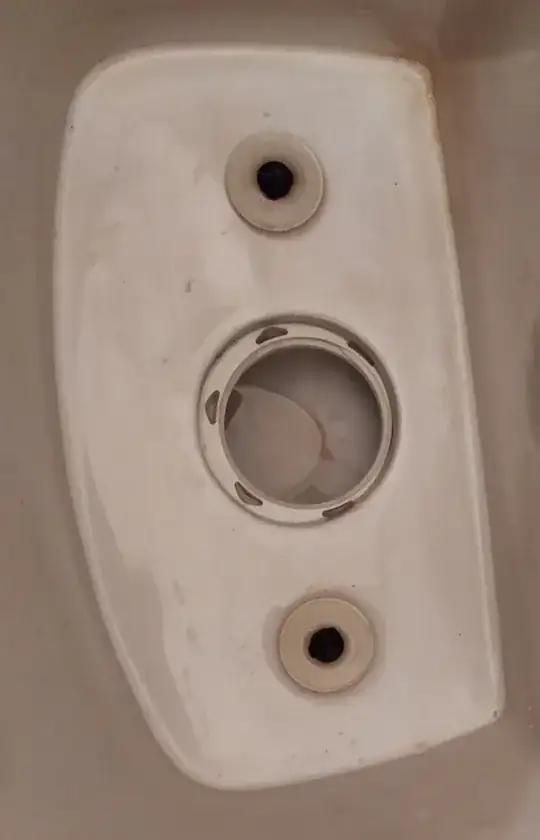

A wingnut:

EDIT: Proper name for wingnuts.

UPDATE: Thanks everyone for the input. Yesterday I was able to remove one wingnut by gripping it really hard with pliers adjustable sized wrench. However, the screw itself is stuck, together with one gasket on the top, and one on the bottom.

The other one moved too a few turns, but it came to the point that now it is rotating together with the screw (and I could not find a way to stop the screw, because the head is so rusted).