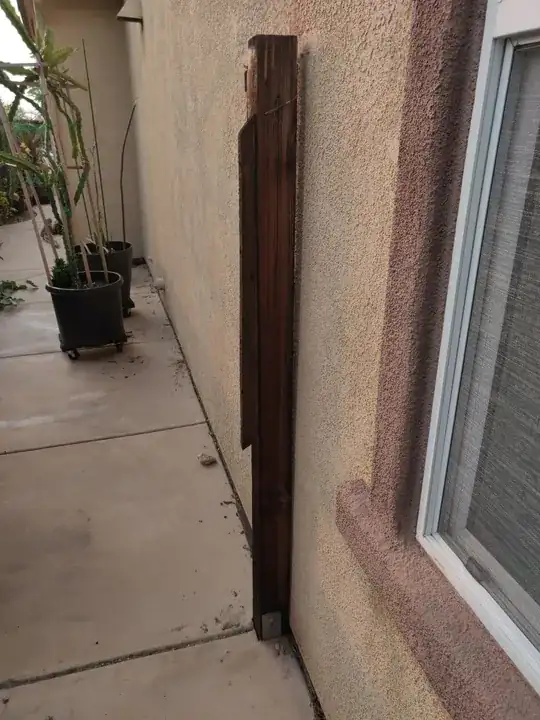

The original 4x4 wood fence post for my home's side gate (that holds the catch part of a gate latch) is very loose and wobbles.

The post is surrounded on 3 sides with my concrete walkway, and the 4th side is right next to my house.

I'm pretty sure the home builder company that installed the posts and fence (and built my home) didn't dig deep when they installed all the posts for my fence, nor cemented the base of each post at all (after 15 years at the house, all the wood posts are in fact wobbly and very very loose).

I'm pretty sure I can just yank out the post (hopefully).

I want to replace the wood post with something like the Halco Postmaster steel post. I was hoping I can get the 8 foot version and somehow get the steel post 2 feet into the ground and then cement it (so that 6 feet of the post stands above the concrete base).

But as you can see from my pictures, the hole is only slightly larger than the 4x4 wood post.

For a proper steel post install, would I need to cut the surrounding concrete walkway to make a 10" or 12" hole, and then dig out a 2 foot deep hole to properly install and cement the steel post?

Or can I still install the Postmaster steel post somehow (e.g., hammering it down with a sledge hammer) down the existing 4x4 hole, but then I can't cement (or pour gravel) down the tight gaps to make it strong and stable, correct?

I read that using something like the Simpson Strong-Tie EZ-base product isn't good/ideal for fences, right?

Something like this:

Any suggestions?

Thanks!