I am not asking for opinions or what is better than the other. I am looking for literature with data that shows the specifications and guidance on how to compare them with each other on a performance level (not cost).

I hope I am using the appropriate nomenclatures here. Correct me if I am wrong please.

- Framing Nail: 16d 3.5 inches long

- Paslode Framing Nails: 3.5 inches long 0.131 diameter shank (PN: 097987)

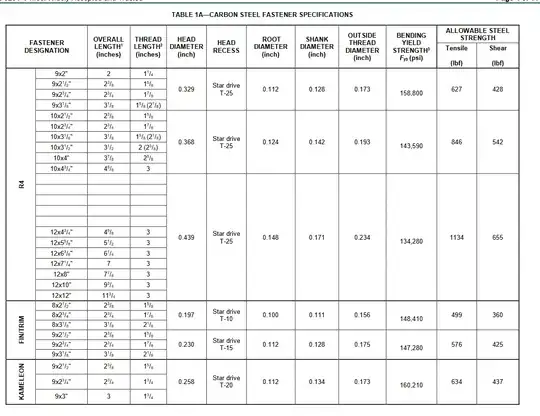

- GRK R4 Multi-Purpose Screw #9 3.5 inches long

- GRK R4 Multi-Purpose Screw #10 3.5 inches long

BTW, I own a Paslode Cordless XP Framing Nailer.

I will be doing some framing that will be inspected by the AHJ. I would like to use GRK R4 Multi-purpose screws for the framing of the 2 by X lumber. Let's assume all fasteners are acceptable by the AHJ.

How do I compare the specifications of framing fasteners?

I presume that Item 1. Framing Nail is the standard.