I have tried both thick and thin blades for cutting rebar. The thick one takes forever and is like smelting a sword. The thin one gets the job done but the blades I selected - limited choices at local hardware store - disappeared after a couple of cuts.

My preference would be to spend more for a good blade with the following characteristics:

- relatively thin so that the amount of material grinded away is less

- but long lasting

- will not disappear causing lockup of the nut (i had to toss away my first grinder for that reason)

Do these types of blades exist? Most of them seem to be 6mm: I'd want 3 or less.

Note: there are two quite different needs:

- cutting rebar to a desired length in a shop - with proper clamps and any leverage I want

- cutting rebar inside retaining wall blocks that sometimes have significant accessibility challenges

For the second case it is critical that the tool be short length. Also I need to be able to cut as flush as possible

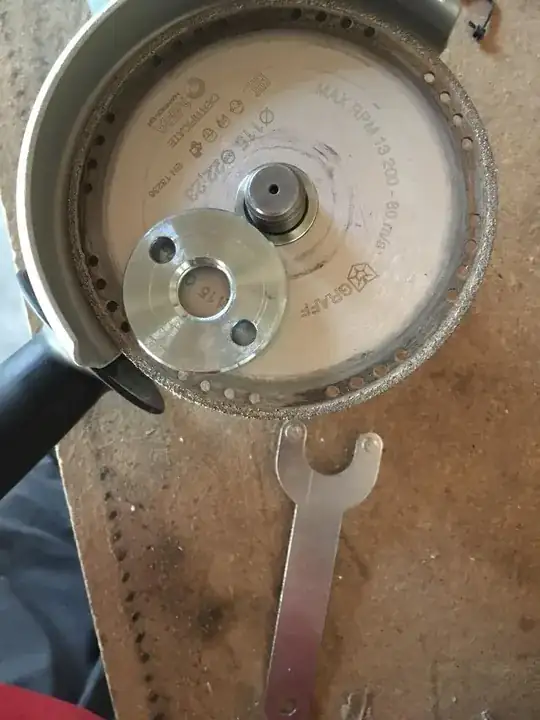

Update I did order this diamond tipped cutoff 1.5mm blade (which @Monkeyzeus had also mentioned in an earlier comment)

I also posted a separate question on how to replace/remove the blade in a locked up angle grinder How to replace grinder / cutoff wheel blades

source: https://www.amazon.com/gp/product/B07Q2B1TBP/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1 .

Will report back after delivery.