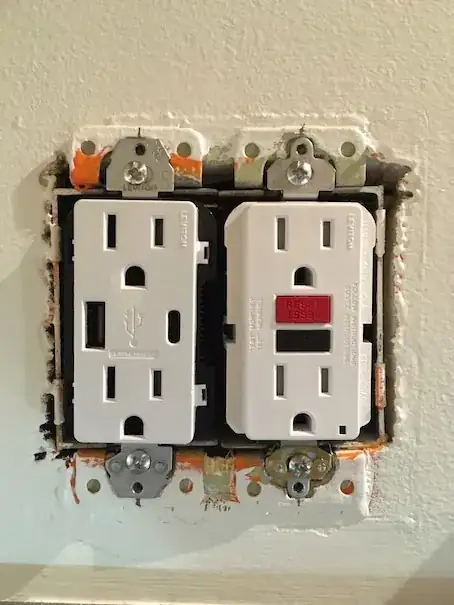

I was replacing outlets and faceplates in my kitchen, finding mostly original electrical boxes or blue old-work boxes, and everything was going fine until I tested a double-gang GFCI outlet and outlet + USB box and saw a lovely purple flash before the breaker tripped.

That's when I realized that this box is actually steel and not gray plastic, and because of the very little clearance, along with a guilty little metal flange, the hot terminal shorted to the grounded box when I tried to reset (turn on) the GFCI outlet.

As you can see from the pictures, there is very little clearance here, but I thought these dual-gang boxes and these GFCI and USB outlets were standard sizes. It occurred to me that perhaps there are plastic inserts available for these steel boxes, but I can't seem to find anything like that. I did find some "low voltage" separators for plastic boxes at the store, but they're too thick. I could easily put some thinner sheet of plastic along the inside edge, but that probably wouldn't be up to code. Nor, I suppose, would be placing electrical tape over the flange and over the outlet side terminals.

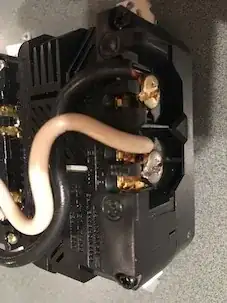

This is the flange where a little bit of it or the GFCI side terminal or both vaporized:

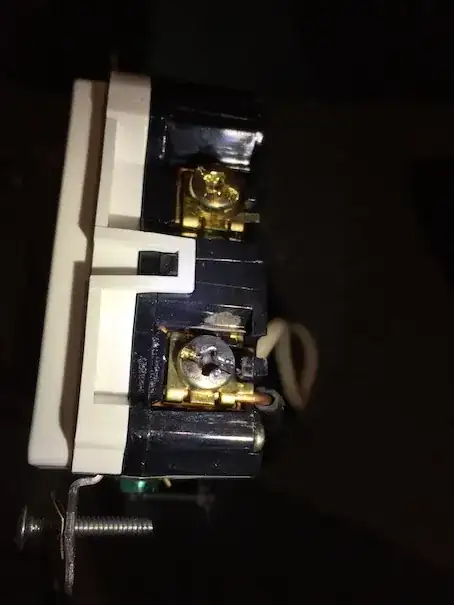

And this is the GFCI side terminal, showing some discoloration on the lower terminal:

This is beside the point, but I connected the USB outlet as a load of the GFCI outlet, and to the best of my knowledge I wired everything properly. Amusingly, the GFCI and the USB outlet are likely still fully functional, but thank God for circuit breakers.

I doubt that I'm the first person who has run into this situation. Was there some way I could have avoided the short without prior experience? (And what is that little flange anyway? There are two on each side of the box, but the other three are flush against the side.) But most importantly, what is the correct way to resolve this without replacing the steel box with a plastic one? These specific outlets are the ones that I wanted to use, but if I am forced to use smaller things that cannot short out, I will have to go that route.

EDIT:

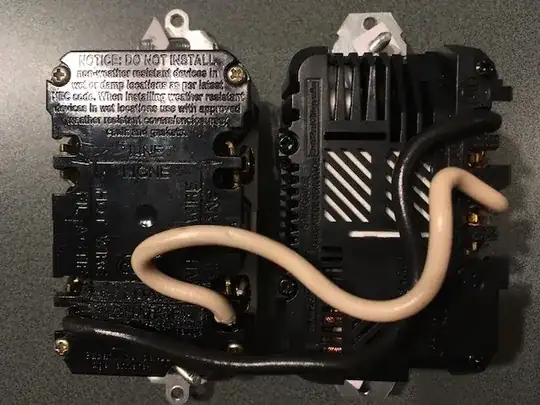

As requested by @J... I am including pictures of the receptacles from the back. The lighting isn't the best, but if you zoom in on the GCFI outlet on the left, you can see the LINE/LIGNE lettering on the top and the LOAD/CHARGE lettering under the sticker residue on the bottom, so I am quite confident that I wired this correctly. The LOAD from the GFCI outlet is wired to the USB outlet. I of course had to disconnect the LINE/LIGNE wires when I removed the receptacles from the box.

And from the sides:

Because the metal flange was touching the LOAD terminal, it makes sense that this only shorted when I tried to reset the GFCI outlet, and apparently the circuit breaker trips faster than the GFCI outlet can react.