Your question states the approximate thickness and height of "ridge" (which I'll term a "tab") of "~2mm thick and ~3mm high". The approximate width is needed for my answer, but only you need to measure it.

I have a medium large set of hex nut drivers with screwdriver handles, which are common tools used in bench electronics disassembly.

So first I'd measure the width of the screw/bolt head's tab (probably termed a "bolt" in motors) with an outside vernier caliper.* Then I'd turn it over, and use the inside vernier caliper to sort through my nut driver socket heads until I found two nut driver sizes that were the closest fits over the inside caliper (as previously set equal to the tab width). Then try both nut drivers on the tab-head, smallest first, and feel if it fits closely (hex corner to opposite hex corner), and then turns.

But warning about what is a coincidental fit. The worse the fit, the less torque you can apply without risk of rounding the tab (bad outcome). Look closely with bright light. If the tool barely starts to turn, but the bolt doesn't, stop, move to the next idea.

This method requires some luck, but at a repair bench (not manufacturing), luck saves time and money.

(*Plastic vernier calipers to use like a ruler are very cheap. Being non-precision, just throw it in the toolbox tray. But it's helpful to pay more for a plastic one that has a measurement lock.)

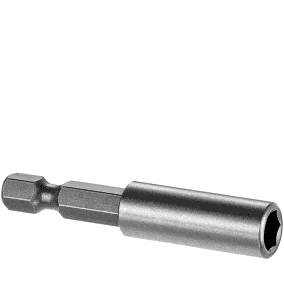

If this didn't work for me, I'd next try the socket extender idea, if you have one, but only if it fits the inside caliper setting closely.

Next I'd personally try the long-reach needle nose vise grip pliers idea. (Because I own one; I recommend this tool as worth the money.)

To make that work, you probably need to lock-grip the tab-head at an angle to the bolt axis (not straight in-line).

Careful, it's easy to round the tab (or any bolt's shoulder head) with careless use of any vise grips. Again use a bright light and watch closely.

The problem is that you don't know without a torque trial (and having skill with setting the vise grips bite pressure), whether the bolt is rusted in place. (I agree with the pre-oil comment, but just a drop while a paper towel is stuffed near, or the motor may stink if the oil heats up later.)

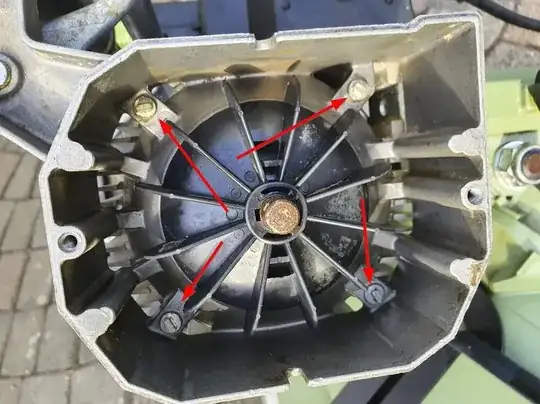

I can't tell for sure from the photos whether you have access to the tab-head's shoulder, or just the tab?

If you have access to the shoulder, first try to remove the bolt by vise-gripping only the shoulder.

The advantage of this trick is that you can bite deep grooves into the shoulder at an angle for more torque (yes, it's ugly), and hopefully break loose a stuck bolt without damaging the tab for later reassembly using normal tab-head driver torque. If you don't set the vise grips bite exactly right (takes practice), and peel or mangle the shoulder when you turn, you get several more tries and hopefully still haven't damaged the head-tab.

Elektra Beckum Machines (now Metabo) was a German company, so the tab-head driver is surely available as a German/EU tool. But, I don't see it named by casually looking at bolt head charts on the web.

(Sorry, not Stackexchange well-formatted, they won't let me.)