I'm trying to save the wood from some wooden pallets and have been unsuccessful. I have been hammering close to where the nails are and then pry the nails out; however, before the wood comes out far enough to remove the nails it usually snaps in half. Any suggestions would be most helpful.

9 Answers

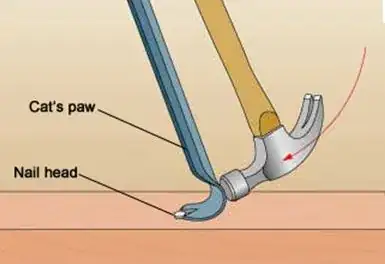

They make several styles of tools that are made specifically for getting nails out. One tool called a "cats paw" looks like the picture below. (You may find similar tool under other localized names). A hammer is used to pound the hooked end in under the nail head so that it can then be levered out.

Another type of nail puller is also very effective in that the tool is used by itself without a need for a separate hammer. The handle on this type of nail puller is used to slide up and pound dowwards to embed the jaws around the nail head. Pulling sideways in the direction of the "foot" forces the jaws to clamp tightly on the nail and pull it out.

- 67,833

- 7

- 68

- 153

For the first few corners you need to cut the nails in half once you have them out a little. Dremel tool with a diamond bit might work. If you pull them out too much they do crack.

- 50,637

- 16

- 93

- 208

I usually collect pallets from the street, because my parents won't buy me wood for me making stuff for my stuff, they only buy it when I'm making their stuff. For the first time I did it, it was so difficult and hard work, I had a whole day of sour muscle but 80%of the hard wood from the pallets had snapped. I recalled the memory that I did it, and found out maybe I should use a chisel and hammer it in between the two timber that are nailed together, and using the pole principle to pull them apart, then use a the end bit of the hammer and use the same pole principle to pull it out. After taking down dozens of pallets, I also had an experience about pull each nail out a bit each time so the timber won't bend and therefore snap. Never use a hammer to try hammer it out, you will damage the timber and snap it as well. Hammer the chisel in and pull it apart.

here's some example of the timber I took down:

- 31

- 1

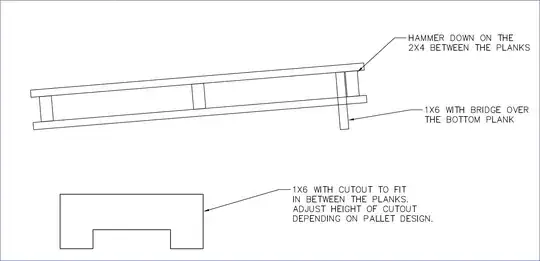

I was very successful with simply cutting a notch in a 1x6. This notch would be for the pallet planks on the bottom side of your pallet so make sure it's big enough to span the largest width plank. Then I would take this 1x6 and set it in between the planks and next to the "2x4" that all the planks are nailed to. This would raise the pallet off the ground +- 1" . I would then take a minisledge and pound down on the pallet. This would create incremental moments of pressure that pulled the planks apart from the 2x4. I would then move my 1x6 to the middle and opposite end section. This loosened 95% of my planks without splitting (which I commonly have happen with just a hammer and crowbar) Then I would use a crowbar to pull on the nail only. It might sound complicated but it's not the only hard part was the constant sound from hammering.

- 508

- 6

- 12

If you can manage to create a gap, a space, by whatever means, between the planks and the structural 2x4s (which planks are nailed to)- - such that you can insert a metal cutting saw blade (hack saw, or reciprocating power saw) then you can carefully cut the nails, closer to the underside of the planks, leaving a small headless nail "stem" on the surface of the 2x4.

Then, use ViceGrip pliers to carefully pullout the remaining embedded nail. Clamp the nail "stem" tight enough such that the pliers don't over-compress the metal stem, and cause it to weaken and snap off; yet firmly enough that the teeth of the pliers can successfully maintain a grip that does not slip off the stem. Practice and intuition will take you through this successfully. By using the curved head of the ViceGrip pliers in a rolling motion, not unlike the curve of claw hammer head, with a gentle yet firm tugging motion, the nail stands a good chance of coming out. Use of wedges, again, not unlike you would with a clawhammer head, will help as well. The object is to place enough of a pulling force on the nail stem, without causing it to sheer off in the process of removing it from the wood.

- 6,319

- 33

- 33

- 43

Let me add a couple of other options to the list.

- For nail heads not completely embedded in the wood, you can use carpenter's pincers.

You work the jaws to the bottom of the nail head, then squeezing the handles provides the leverage to get the jaws under the head. From there, you can easily lever the nail out enough to pull it with a bigger tool, cut it off, or reposition the pincer to pull it out. Some pincers have a hardened head and allow you to cut softer nails if you have a lot of hand strength.

- Another approach if you do this a lot and have an air compressor, is to use a pneumatic nail remover. They aren't necessarily expensive. One of the first ones I spotted on Amazon was under $50, and I wouldn't be surprised if Harbor Freight has a $20 version. :-)

You use this to remove nails after pulling the boards apart. You slide the snout over the protruding nail (may need to straighten the nail if its bent over). A ram knocks the nail back out of the wood. Here's a video that shows it in use starting at 3:00 minutes in: https://www.youtube.com/watch?v=AEejvcNBoCg

A clever guy made a manual version with an impact driver bit holder. Here's a video: https://www.youtube.com/watch?v=LWeEbYYySLw The video is way longer than it needs to be. The relevant part starts a minute into the video, and how to use it starts at 3:30 (you can figure out the first part if you watch starting at 3:30).

- 6,228

- 5

- 32

- 51

I used a FEIN saw with metal cutting blade and then a punch attached to a palm air hammer and that took out nails real fast. Very fast work taking apart a pallet no damage except where the nails were pushed back through on some that were sunken in the wood.

Obviously you can use specialized equipment like Dan Padilla suggests, but I will assume you don't have such equipment.

You need to lever across both sides of the nail which is hard to do with a hammer. Use a nail puller and wedge it into the crack where the plank is nailed to the joist.

If that isn't working for you, get a hacksaw and cut in the seam where the two pieces of wood meet. After they are apart use a nail set (a small metal pin) to knock out the nail.

- 6,971

- 13

- 66

- 113

Use 2 strong planks + 2 strong supporting planks like this: https://www.youtube.com/watch?v=TWnj4fUhyjI

- 11