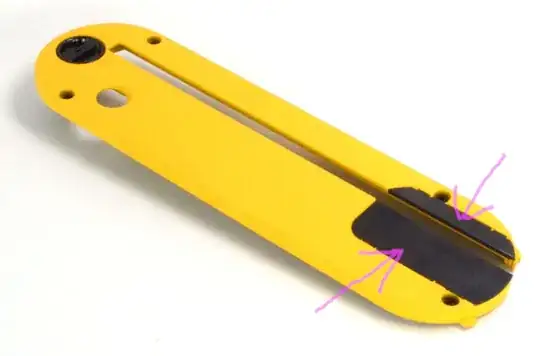

I have a DeWalt table saw. The throat plate looks like this. Sometimes I have a problem with the work piece sticking as I'm pushing it through, and the culprit is one of those black metal bits indicated with arrows. They're not tightly attached to the body of the throat plate, and they protrude ever so slightly. The throat plate seems to be made of some sort of lightweight cast metal (maybe aluminum or magnesium) and the black bits are stamped steel, so I assume they couldn't weld them together.

What I want to know is, what the hell is the purpose of these steel parts? Why couldn't they just make the whole plate out of one solid piece of metal?

I looked at the table saws that were on sale at my local store, and all of them had something similar, so it's not specific to DeWalt. But I also see aftermarket throat plates that do not have it.