Consider how this wood is created: melamine-coated MDF is wood fibers mixed with binder and pressed into a sheet, with a plastic laminate applied to the surface. The photo seems to show that the white plastic layer has been pulled up and torn.

Perhaps you're using an ordinary twist drill? These are pointy (maybe sharp; maybe not) in the center and along the cutting edge but they definitely lack a sharp cutter for the outer circumference of the circle.

Other drilling/cutting tools are designed to give a very clean outer edge, particularly in soft or loose woods like MDF. Because these cut the outer edge first, tearing that occurs in the middle won't extend outside the hole.

A web search for "12 mm forstner" brings up for me several Forstner type cutters, but also brad point bits that look like they'd do a good job. These are the kinds of tools a professional or factory would use.

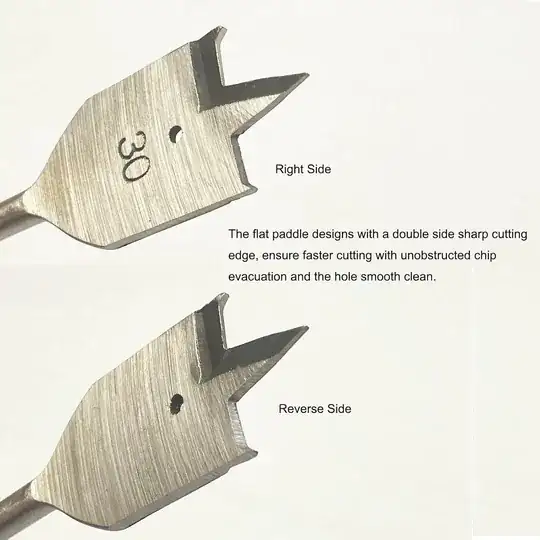

If you're careful and drill slowly, even a conventional hole saw or spade bit will probably leave a cleaner result than what you're getting now.

There might yet be hope for the lowly twist drill. When the masking tape trick doesn't help, firmly clamping a sacrificial scrap of wood on top of the workpiece then drilling through the assembly can reduce the potential for the workpiece surface to lift and tear.