Why do electricians prefer not to use the back-stab or quick connect holes on switches and receptacles? If these were unreliable do you think they would be allowed by the NFPA and NEC?

7 Answers

The sockets I've been using for the last 15 years have standard screw connection, holes behind that location where the screw pulls a plate against straight stripped wires and the push-in holes.

After you've encountered a few burnt sockets from using the push-in connection in the first couple outlets in a daisy chain, you start to realize something.

The straight connections behind the screw are mechanically sound and require only a wire stripper and a screwdriver. You don't really save much time using the push-in.

Hoping and wishing that brass retains its spring pressure to maintain a tight, low resistance connection on the push-in connector after many heat cycles anneal it, doesn't make the connection mechanically sound.

When the spring pressure relaxes as the metal loses its work hardening, you are left with a loose connection which heats, further anneals the brass spring and then proceeds to get hot enough to melt the supporting plastic shell.

Afraid to burn a house down during its lifetime? --OR-- Proud of sturdy craftsmanship that only takes a wire stripper and a screwdriver to make a solid, permanent connection?

Take your pick on how you word it, I'd rather err on the side of wearing the socket out from use, not having to replace it due to burning and melting from a loose connection.

Further observations:

On the mechanical connections: Brass has a similar coefficient of expansion as copper so is slower to loosen if tightened properly. This is one of the reasons why the old copper wire only sockets would fail with aluminum wire.

Due to daisy-chain failure, I once sectioned the side out of a new socket to verify "spring-loading" in the push-in contact. As copper wire is flexed, it work hardens. This allows the wire to put side pressure against the spring contact as the socket is pushed back into the box for mounting which can slightly unseat the connection. The lessened contact pressure causes resistance. Heat eventually anneals the spring causing it to lose its "tightening" ability leading to enough heat to melt the plastic supporting the contact. That observation is from disassembling a failed socket and the closeness that the hot conductor came to the others after burning/melting the support plastic was not good.

If you look up the receptacle specifications, the push-in is rated for 14 gauge wire. If your circuit breaker is 20 amp, you will be using 12 gauge wire and have to use screw head or straight in mechanical connections.

- 12,399

- 3

- 24

- 51

- 11,431

- 1

- 29

- 44

It's not that we are afraid of anything. It's that it makes poor business sense to use such a failure prone connection. Thing is, they are just unreliable. It's not that they are unsafe.

- 16,708

- 2

- 29

- 54

Push-in's (i.e. back-stab terminals) were popular in the 70's and a failure as most of the comments refer to. However, as I like to say, The new push-ins are not your fathers push in. You will be hard pressed to even find a screw in connector in Europe. Schneider, a large electric manufacturer who also owns Square D, does not make screw type connectors in their outlets or panels in the European market. A infrared camera picture of the screw in vs the new push in showed a substantial heat source (can you say "loose connection?") on screw-in vs the new-style push-in. We are hard to change but current technology every place other than the US supports the new-style push in terminals.

- 87,685

- 36

- 144

- 243

- 39

- 1

Yes, unreliable devices are allowed by electrical codes. Further than that, unreliable devices are sometimes MANDATED by the electrical codes: AFCI circuit breakers, for instance. The fact that the manufacturers of these devices have a great deal of influence in the bodies that create the codes may explain this situation.

- 4,598

- 16

- 17

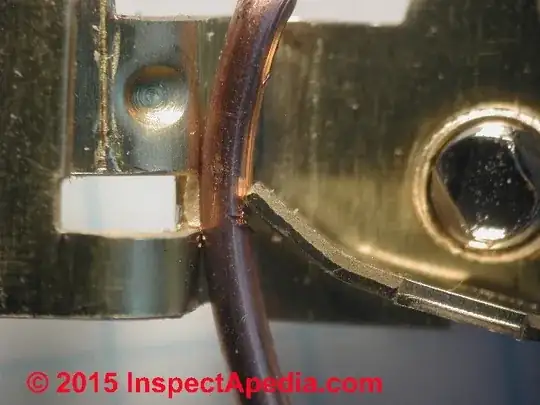

Do you see the connection? Two thin edges and and one of them where there is damaged wire. This can create hot spots that are invisible outside of the device. As the metal heats and cools over its life time the connection and become weaker making it get hotter.

Compare this to wrapping a the wire around a screw, which tightens up as you tighten the screw. Anyone can visually inspect the latter while the above picture you would never see. I myself use pigtails when connecting devices whenever I can. This way if there is device failure it is localized instead of taking out the rest of the circuit.

Some people choose to use the cheapest, fastest and sloppiest work they can to complete a job. Yes it might be OK 1,000 times but that 1,001th time when it fails it could not be their fault, oh no it must be a manufacturing defect or some such. When these types of connections fail it is usually immediately or years down the road. Which means fixed then or it is past their warranties. Small condolence when someones house burns down.

- 26,498

- 8

- 44

- 100

- 21

- 1

The biggest problem in services is the client. Imagine you've wired whole house with push-ins but then the client decides he/she wants the light switch on the other side of the door, or the sockets in different color. With screw connections, you can disassemble and reassemble the installation. Without screws - you're screwed.

- 1,680

- 11

- 13

Not only that, but a 5% drop in voltage at any point from the panel is "recommended" as the maximum voltage drop. When I had my previous house built in 1996, the apprentice ran so much wire up and down the walls, that i hat a 15% drop in my bedroom. I threatened to call the state wiring inspector if it wasn't fixed. It was. Push in contacts can also lead to more voltage drop through contact resistance.

- 756

- 5

- 6