I'd like to build a largish (6' x 7' x 4') structure that can be assembled and disassembled on-site with only hand tools. I'm thinking about things like insert nuts, cam lock nuts, mortise/tenon joints locked in by Ikea-style nut sleeves. But generally, I can't tell whether "disassemblable" just means "not sturdy" or "will only last for one or two assemblies."

Is this a realistic goal? Are there fittings that fit this bill, or do I have to choose between permanent and not sturdy?

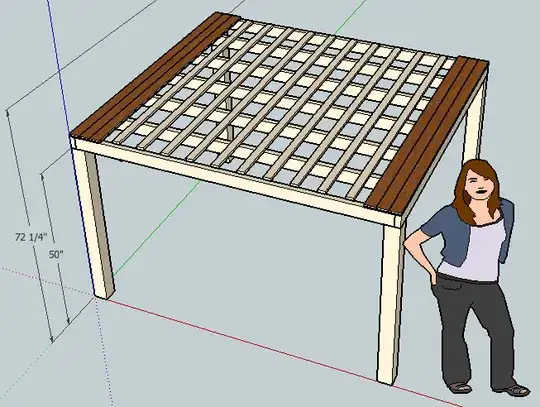

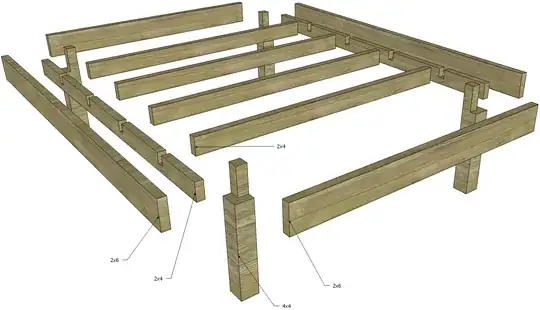

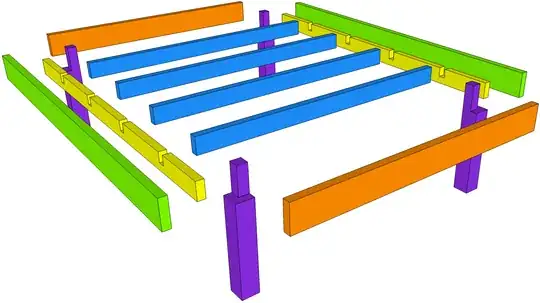

I mean the question generally, but right now I'm thinking about the various joints needed for the structure below (loft platform for king sized bed, basically slats on joists on 4x4s):